E D R O

D

y n a

W

a s h

®

T

h r e e

P

o c k e T

W

a s h e r

- e

x T r a c T o r s

57

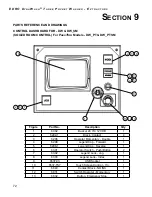

Inverter with Single Motor Drive Models Only (Below)

• Monitor/Adjust the Y36 & Y20 brake pressure gauge outputs for the best site specific

performance.

• Grease bearings every 50 hours of operation. If bearings become noisy, it does

not necessarily mean they have to be replaced. Usually it is a lack of grease, but

sometimes they may have to be adjusted for less clearance. Check the weep hole in

the bearing adapter frequently for leaks. Water droppings from this area indicate seal

failure.

• Change oil in the reducer after the first 100 hours of operation, then once every six

months.

(2 - Motor Drive Models Only)

• Motors should be greased only once a year.

• Drain water from air filter and refill oil jar as needed.

• Keep belts tight, especially on wash motor.

PERIODIC MAINTENANCE REQUIREMENTS

2 - Motor Drive Models Only (Below)

• Check at least once the similar taper bushing screws on the clutch, as they have a

tendency to loosen up from heat and constant jogging.

• The initial wear on the disc brake will be more rapid in the first few weeks and the

brake should be adjusted as needed. Air pressure regulator gauge should be

adjusted to at least 40 PSI.

• The brake on the wash motor needs less adjustment and should not be tampered with

unless the indicator on the motor points to “adjust”. When adjusting, make sure the

electricity is off and that the gap between the coil and lever is ½” so the braking action

will work at its best.