E D R O

D

y n a

W

a s h

®

T

h r e e

P

o c k e T

W

a s h e r

- e

x T r a c T o r s

62

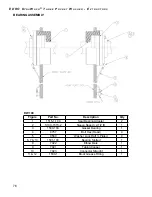

Solid Seals

1. Point seal lip in correct direction; away from the cylinder, facing the bearing.

2. Protect seal lip against damage from sharp keyways, splines, screw-threads.

3. Start seal into cavity by finger pressure, then tap evenly all around until seated or flush with

housing face. Tap only on outer edge of seal.

NOTE

Lubricate shaft and lip of seal. Always clean cavity and

shaft when replacing seals or bearings.

WARNING

Never cut solid seals for adjustment to fit on shaft.

Model

DW100

DW150

DW200

DW300

DW400

Shaft Size

2-½

3”

3”

3-½

3-½

Collar Set Screws

680 in./lbs. 680 in./lbs. 680 in./lbs. 680 in./lbs. 680 in./lbs.

Mounting Bolts

90 ft.lbs.

140 ft.lbs.

140 ft.lbs.

320 ft.lbs.

320 ft.lbs.

BEARING TORQUE REQUIREMENTS