E D R O

D

y n a

W

a s h

®

T

h r e e

P

o c k e T

W

a s h e r

- e

x T r a c T o r s

65

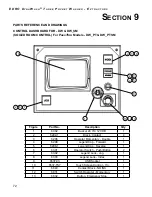

TROUBLESHOOTING PROCEDURES

A list of symptoms directs attention to specific components and possible causes of the machine prob-

lems. The type of malfunction and identification of the component then permits a logical decision to

repair, replace or investigate further in order to correct the fault. A complete loss of control may be

caused by two malfunctioning components acting together, repair of one cause may restore operation,

but it may also permit a recurrence if the second malfunctioning component is not repaired. For refer-

ence the following is a complete listing of PLC input and output devices. Refer to electrical schematic

for additional details on machine wiring logic.

X0:

Wash Overload

X1:

Extract Overload

X2:

VFD Overload

X3:

Vibration

X10: Drive Running

X20:

Door Position Closed

X21:

Ozone Pump 1 C.O.S.

X22:

Powercell 1

X23:

Powercell 2

X24:

Powercell 3

X25:

Ozone Pump 2 C.O.S.

X26:

Powercell 4

X27:

Powercell 5

X30:

Powercell 6

X31:

Supply Air Pressure Sensor

X32:

Door Open Limit Switch

X33:

E-Stop 1

X34:

Tilt HOME Limit Switch

X35:

Flasher Limit Switch

X36:

Tilted Limit Switch

X37:

Door Pin Sensor

X40:

Jog (WS)

X41:

Powercell 7

X42:

Powercell 8

X43:

E-Stop 2

X44:

E-Stop 3

X45:

E-Stop 4

X46:

FWD Tilting Bearing (Locked)

X47:

FWD Tilting Bearing (UnLocked)

X50:

REV Tilting Bearing (Locked)

X51:

REV Tilting Bearing (UnLocked)

X52:

Index Proxy Sensor

X53:

Thermguard Switch Extract MTR

X54:

Index Switch PB (CS)

X55:

Forward (CS)

X56:

Reverse (CS)

X57:

Switch 0

X60:

Switch 1

X61:

Lock (WS)

X62:

Job (CS)

X63:

Signal (WS)

X64:

PT CS Button

X65:

Clutch Air Pressure Sense

X66:

Door Open Prox Switch (CS)

X67:

Door Closed Switch (CS)

Y0: Forward

Y1: Reverse

Y20: Brake

Y21: Waste Drain

Y22: Ozone

Y23: Buzzer 1

Y24: Door Pin

Y25: Cold Water Valve

Y26: Hot Water Valve

Y27: Door Auto Swing

Y30: Chemical 1

Y31: Chemical 2

Y32: Chemical 3

Y33: Chemical 4

Y34: Chemical 5

Y35: Auxiliary Supply 1

Y36: DW VFD HSB

Y37: Electric Heat/Steam

Y40: Auxiliary Supply 2

Y41: Auxiliary Supply 3

Y42: Auxiliary Supply 4

Y43: Auxiliary Supply 5

Y44: Tilting Air Bag - Inflate

Y45: Water Reuse (WRS) Drain

Y46: Water Reuse (WRS) Valve

Y47: Index Door Seal (CSL-T)

Y50: Tilt FWD - Locked Cylinder 1 (CSL350/450)

Y51: Tilt REV - Locked Cylinder 2 (CSL350/450)

Y52: Green Light

Y53: Yellow Light

Y54: Red Light

Y55: Air Source Shutoff Valve

Y56: Spray / DW Jog Valve

Y57: Tilting Air Bag - Deflate

Y60: Doorpin 2 (CS)

Y61: High Extract

Y62: Low Extract

Y63: Clutch

Y64: Buzzer 2

Y65: In Use Light

Y66: Lock Light

Y67: PT CS Lite

PLC INPUT FUNCTIONAL DESCRIPTION

PLC OUTPUT FUNCTIONAL DESCRIPTION