3

EDS - TECHNICAL INFORMATION

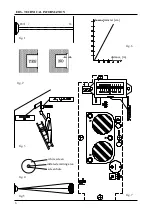

4 - OPTICAL ALIGNMENT

4.1

- Go on with the optical alignment between the

device and the FX reflector. To make this operation

easier, it is suggested to do it in a reduced

environment light, and to proceed in the following

way:

a) Shift the JP2 jump to position 2-3 and rotate

the P4 internal trimmer for the sensitivity

regulation fully clockwise (to the highest

sensitivity). See P4 trimmer in the scheme fig. 8.

b) Place a lamp that can emit a concentrated

and sufficiently bright beam in front of the reflector

(we recommend our LAL02 lamp - power supply:

battery 12V-6Ah). Point the lamp beam at the

trasmitter lens (see fig. 3).

c) Observe the screen which is behind the lens

inside the transmitter(right lens) from the lateral

window. You will see a bright point representing

the lamp image. Adjust the transmitter's direction,

using the proper B screws and the key included,

so that the bright point lays right in the center, where

there's a small hole through which you can see the

photodiode. It’s important that the bright point falls

exacly in the center of the photosensitive element.

This area is represented by a small dark square at

the center of the photodiode (see fig.4). With this

procedure the device will be optically aligned with

the reflector.

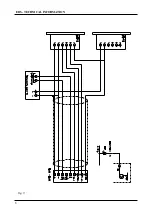

5 - SETUP

5.1

- Power up the device. If the previous optical

alignement operations have been carefully carried

out, the following conditions must be found:

internal red LED light switched off

internal yellow LED light switched off

alarm relay R not powered or powered.

This depends on the position of the JP3 jump (see

fig. 8)

buzzer or LED connected to the OC output

terminal not powered (see fig. 9)

voltage at terminal TP1 (see 3.1) higher than 3 V

5.2

- Looking at the instrument's measure

(connected between TP1 and negative terminal)

adjust the V screws slowly to obtain the maximum

output signal. If this operation is not sufficient to

obtain a good output, it means that the optical

alignment with the reflector has been done

incorrectly.

5.3

- The transmitter emits a conic beam, whose

form and size related to the distance between the

transmitter and the reflector, are shown in the

figures 5 and 6. It is important that the reflector is

in the center of the beam emitted by the transmitter,

because in these conditions, even if some small

movements of the wall or surface on which the

device is assembled occur (caused by the strains),

the reflector always remains inside the beam. To

obtain this, the delicate truing operation with signal

measure as decribed in points 4.1and 5.2, must be

carried out with the greatest care. Attention: since

the device bases its working on the reflection of

the emitted beam, this reflection must be realized

only by the FX reflector, not by other elements.To

make sure that this result is obtained,

the reflector

must be obscured

by a not-reflecting panel. In this

case the instrument (connected between TP1 and

negative terminal) must indicate a voltage under 2

V (read further instructions).

5.4

- Adjust the sensitivity operating on P4 trimmer

and remembering what follows:

high sensitivity is obtained with signals between

3 and 5V (between TP1 and negative terminal)

medium sensitivity is obtained with 5-8 V

low sensitivity is obtained with 8 V or more

Remember that the adjusted signal is subjected to

a lowering of about 1 V when the device cover is

assembled, due to the frontal mask absorption.

Therefore the signal must be increased of about

1 V to be obtain a perfect adjustment.

5.5

- The sensitivity is to be adjusted according

to the environmental situation. Normally the level

is set for a medium sensitivity, but in case of dusty

environments (furniture factories, ecc) it is better

to use a lower sensitivity (8 V and over).

5.6

- The device is factory set to work with normally

not powered relays. If you wish to have the opposite

situation operate on the JP3 jump as follows:

pos. 1-2 normally powered relay

pos. 2-3 normally not powered relay

Remember that in pos. 2-3 the device

comsumption passes from 14 mA to 28 mA.

6 - WORKING TEST

6.1

- Verify the detector's working putting a not

reflecting panel

in front of reflector

. As soon as

the signal drops under the treshold level of

prealarm (3 V), the yellow LED must flash.