3

EDS - TECHNICAL INFORMATION

1.9

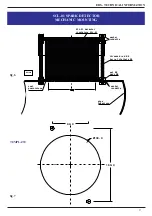

- The detector has two internal settings (Figure

2)

- sensitivity level adjustment

- adjustment of the duration of the time of activation of

the output relay (using the jumpers JP3-4-5-6-7)

They must be adjusted to achieve optimum perfor-

mance

1.10

- The detector is equipped with internal

microprocessor which not only provides the operation

and check of electronics, but also provides the check

of the status of internal components. In case of fault

an output signal (FAULT) is generated. Also +5V is

generated on terminal 4 and it can be used for a

remote indication of a fault. The maximum generated

current is 10mA.

1.11

- The detector has a field of view of 90 ° (solid

angle) and is suitable for pipes with a diameter up to

50 cm. If the diameter is larger, or if the pipe section

is square, rectangular, etc.. to avoid dead zones

outside the field of view of the detector and have

ensure detection, we recommend using two detectors

installed diametrically opposite on the pipes surfaces.

1.12

- The output relay can be conveniently used to

actuate a solenoid valve that feeds a sprinkler spraying

nozzle to perform automatic extinguishing of the spark

in the pipeline. This nozzle therefore sprinkle water

for a time set by the setting of jumpers JP3-7

(adjustable between 0 - 10 seconds). We recommend

a time of about 5 seconds.

1.13

- When you want to be sure of the success of

extinguishing or in important plants, where security

must be at the highest level, we suggest to install a

second detector (or detectors couple) at a certain

distance from the first one, in order to have a second

check of extinguishing and if necessary a second try .

If the spark has already been extinguished the second

detector will remain inactive. Otherwise it react and

its output relay contact can be exploited to:

- activate a second sprinkler spraying nozzle for a

second extinguishing attempt

- activate a door shutter to prevent the spark from

being introduced into the silo

- activate a suitable audible warning

2

- OPERATION VERIFICATION

2.1

- to verify the operation of the detector after

installation and the adjustments described in the

chapter 1, you must:

- power on to the detector

- wait 1 minute to allow the microprocessor to ope-

rate the various settings

- press the TEST button remotely connected to

terminals 6-5. If you use the EV521 control panel,

press the TEST button present on the front of the

unit or press the remote button connected to the

17-18 terminals of the control panel.

If you are not using the TEST button to check the

operation of the detector it’s necessary to cause a

real spark in his field of view. This must be done

only after taking adequate security measures

3

- SYSTEM OPERATION

3.1

- With reference to fig. 5 relating to a system

with two detectors, if a spark passed in the viewing

field of the first detector, the detector SCL-01 enters

in alarm condition, and its output relay is energized

instantaneously and remains energized for an time

adjustable between 0-10 seconds (JP3-7). The

output contacts of this relay will be used to operate

the electrovalve VL1, which will cause the

intervention of the SS1 spraying nozzle for a first

extinguishing attempt.

3.2

- If the spark has been extinguished, the system

returns to the initial state of normal operation.

Otherwise the spark, continuing his flowing, will enter

in the viewing field of the second detector SCL-01.

This will activate its output relay. The output contacts

will operate the electrovalve VL2 causing the

activation of SS2 nozzle SS2 for a second

extinguishing attempt shutdown

4

- RESPONSE TIMES

4.1

- The time delay to be taken into account in the

design of a spark detection system are as follows:

T1 - operating time of the spark detector SCL-01

T2 - operating time of the relay output of the spark

detector

T3 - signal processing time and operating time of