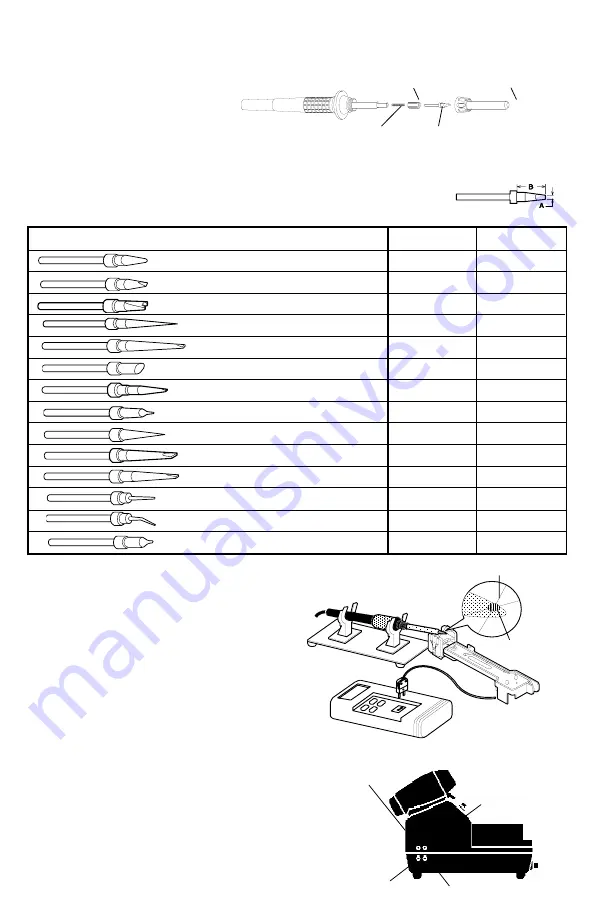

REPLACING TIPS

Part No. & Description

a

b

LT374 Standard Probe .03 (0.8 mm) .48 (12.2 mm)

LT375 Standard Spade .06 (1.5 mm) .48 (12.2 mm)

LT376-7 SMD Channel .12 (3.0 mm) .48 (12.2 mn)

LT392 Extra-Long Needle .02 (0.5 mm) 1.13 (28.8 mm)

LT394 Extra-Long Spade .07 (2.0 mm) .93 (23.6 mm)

LT399 Large Face .17 (4.3 mm) .49 (12.4 mm)

LT444 SMD Mid-Length Fine Spade .04 (1.0 mm) .78 (19.8 mm)

LT446 SMD Probe .03 (0.8 mm) .48 (12.2 mm)

LT382 Long Cone .02 (0.5 mm) .62 (15.6 mm)

LT395 Mid-Length Stubby Spade .09 (2.3 mm) .74 (18.8 mm)

LT431 Mid-Length Spade .07 (1.8 mm) .74 (18.8 mm)

LT439 SMD Thin Probe .03 (0.8 mm) .50 (12.7 mm)

LT439-1 Same as LT439, Angled

LT445 SMD Angle Face .03 (0.8 mm) .48 (12.2 mm)

General Purpose Soldering Tips

Iron Plated for long life•Nickel and Chrome Plated for optimum heat transfer.

EDSYN has over a 100 varieties of standard and custom-made Tips. CONTACT EDSYN FOR MORE SELECTIONS.

CHANGING TIP for 981

1. MAKE SURE YOUR TOOL IS

COOL!

2. Turn Retaining Sleeve counter-

clockwise to remove.

retaining sleeve

accumulator

grounding

spring

3. Remove old Soldering Tip.

4. Insert new Tip.

5. Install Retaining Sleeve.

thermocouple

solder

LO Digital Panel

Meter

Cal. Pot

LO Tip Temp. Cal. Pot

HI Tip Temp. Cal. Pot

HI Digital Panel Meter

Cal. Pot

CALIBRATION SET-UP USING MS412

1. Install desired Soldering Tip.

2. Turn on power and set Temperature Control Knob to 400°F

(205°C).

2. Apply a small amount of solder on the Tip, just enough to form a

bead on top of the Tip.

3. Place the center of the thermocouple wire of the SDS100 on top

of the bead.

4. Again, apply a small amount of solder on the center of the thermo-

couple wire, just enough to embed the center.

TEMPERATURE CALIBRATION

AIR MOVEMENT WILL AFFECT THE TEMPERA-

TURE READING. WORK IN AN AREA WHERE

THERE IS MINIMUM AIR MOVEMENT.

1. Do "calibration set-up using MS412" procedure (above)

2. Set Temp. Control Knob to MIN.

3. Adjust LO Tip Temp. Cal. Pot so the Digital Panel Meter will read

385°F (196°C).

4. Set Temp. Control Knob to MAX.

5. Adjust HI Tip Temp. Cal. Pot so the Digital Panel Meter will read

825°F (441°C).

6. Set Temp. Control Knob to MIN.

7. Adjust LO Digital Panel Meter Cal. Pot so the Digtal Panel Meter will

read 385°F (196°C)

8. Set Temp. Control Knob to MAX

9. Adjust HI Digital Panel Meter Cal. Pot so the Digital Panel Meter will

read 825°F (441°C)

soldering tip