Original operating manual

Pneumatic circular saws

OM No.: 001 580 654

4 of 19

Version

26.06.2018

1. Use, scope of supply,

accessories

General information concerning the proper

use of the equipment

– please read this

section carefully!

This manual is intended for the machine

operator. Keep this manual accessible at all

times.

The pneumatic circular saw may only be

operated:

in a perfect technical state, in line with the

intended use, in consideration of all of the

safety- and hazard-relevant aspects,

with all the safety devices attached,

in compliance with the safety instructions,

after the operating personnel have read

and understood these instructions,

particularly Chapter 3 Safety Instructions

and Chapter 4 Connection and Startup.

It is assumed that the operating personnel

is sufficiently familiar with the use of

pneumatic circular saws. Instruction is

provided by our specialist personnel.

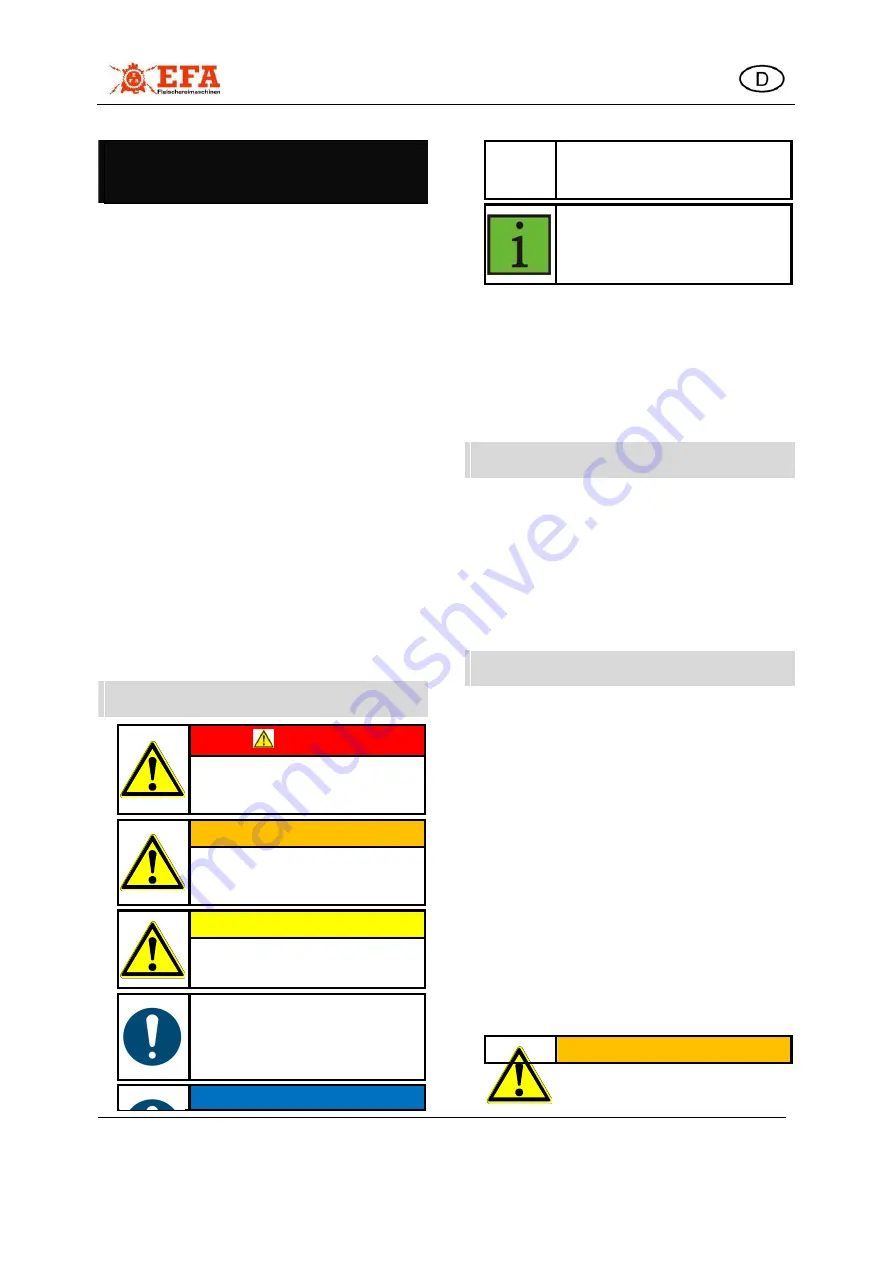

1.1 Symbols used in this manual

DANGER

Death, severe injury, or significant

property damage

will occur

if

proper precautions are not taken.

WARNING

Death, severe injury, or significant

property damage

may occur

if

proper precautions are not taken.

CAUTION

Minor Injury may occur if proper

precautions are not taken.

Mandatory sign

Danger to individuals who do not

follow the instructions given by the

corresponding symbol.

ATTENTION

Damage

to

property

or

the

environment may occur if the proper

precautions are not taken.

Text passages marked with this

symbol

provide

essential

information and useful tips.

1.2 Intended use

Depending on the design, the pneumatic

circular saw is designed for light and

demanding breaking, particularly for sawing

ribs in pigs and for cutting cattle, calves, and

game.

Pneumatic circular saws from Schmid & Wezel

(S & W) comply with the relevant safety

regulations.

1.3 Improper use

The machine is not equipped for a different

type of use. If the operator wishes to use the

device for other purposes, please consult

Schmid & Wezel GmbH (S&W) in advance.

We would like to point out that improper use

leads to greater risk of accidents and

increased wear. In the event of non-

compliance, the liability shall be borne by the

user alone.

The pneumatic circular saw may pose a

hazard

if

untrained

personnel

use

it

inappropriately or for improper purposes.

WARNING