Schmid & Wezel

D 75433 Maulbronn

Seite/ Page

17/ 27

Ausführung/ Version

05.2007

Turn the screw in MINUS direction until the saw

is hanging freely in equilibrium (with the spring

balancer) at working height.

If the saw cannot be pulled out, the spring balancer

is jammed and a readjustment is necessary:

Turn the screw in PLUS direction until the saw

can be pulled out and start the fine adjustment

again (see above).

5. Maintenance

Malfunctions may occur during operation, but these

are generally relatively simple to remedy. Table 2:

Troubleshooting lists these malfunctions with possi-

ble causes and resulting potential remedies.

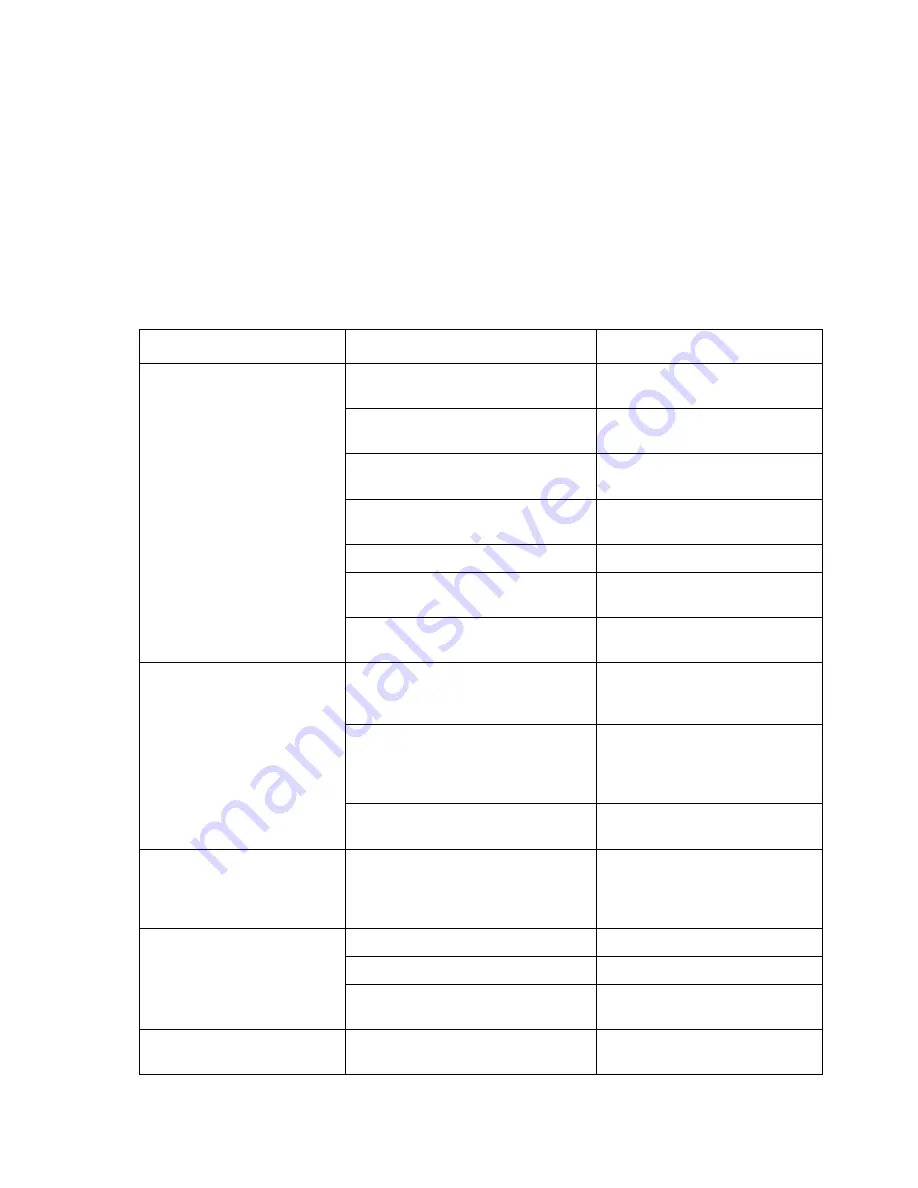

Table 2: Troubleshooting

Malfunction

Possible cause

Remedy

Turn on switch (31), the motor

does not start

1. Connection to works mains defec-

tive

Inspect the connection and

repair, as necessary

2. Circuit breaker of works mains

FAULT

Inspect the circuit breaker, switch

on again or replace

3. Switch (31) defective or connec-

tion loose

Check contacts and connection,

replace switch if necessary

4. Core in lead (22) broken or defec-

tive

Inspect lead (22) and replace, if

necessary

5. Fuse (42) defective

Inspect, replace if necessary

6. Field winding (2) or armature (5)

defective

Inspect, replace if necessary

7. Carbon brushes (15) worn

Inspect, replace if necessary (see

chapter 4.4)

Turn on switch (31), the motor

starts,

motor becomes hot, saw

blade running

8. Ventilation slots in motor housing

(1) or intermediate flange (9) are clo-

sed/clogged

Clean and open ventilation slots

again, then clean the motor (e.g.

air)

9. Fan on armature (5) broken

Replace the complete armature

(5),

the fan is not available as a spare

part

10. Field winding (2) or armature (5)

defective

Inspect, replace if necessary

Turn on switch (31), the motor

is blocked

11. Fan on armature (5) broken

Replace the complete armature

(5),

the fan is not available as a spare

part

Turn on switch (31), the motor

starts, saw blade does not run

11. Fan on armature (5) broken

Inspect, replace if necessary

12. Pinion (8) broken

Inspect, replace if necessary

13. O-rings (82) worn

Ring gear runs with drive.

Inspect, replace if necessary

Saw blade does not come to a

standstill within 3 seconds

14. Brake electronics (20) defective

Inspect, replace if necessary