EFA breastbone cutter Z 10 D

Translation of the operating instructions

EN

V 05.2021

10 of 21

3.1

Dimensions

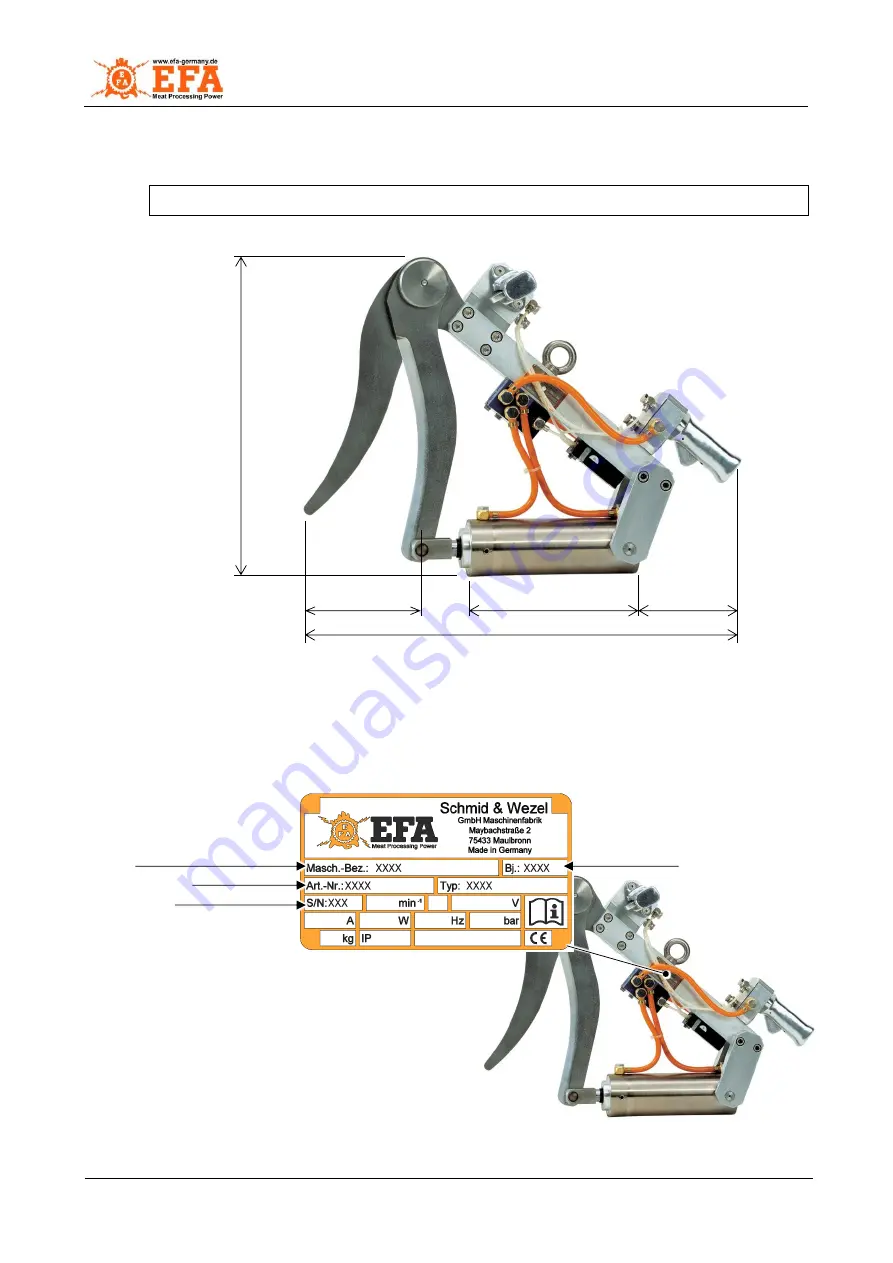

The following figure gives you an overview of the dimensions of the

EFA breastbone cutter

.

EFA Z 10 D

(part no. 130106800)

3.2

Nameplate

The nameplate is attached to the machine and contains information on the machine performance.

The following figure shows an example of the nameplate for the EFA machines.

Machine designation

Part number

Serial number

Year of production

130

250

130

510

475