EFA breastbone cutter Z 10 D

Translation of the operating instructions

EN

V 05.2021

16 of 21

X

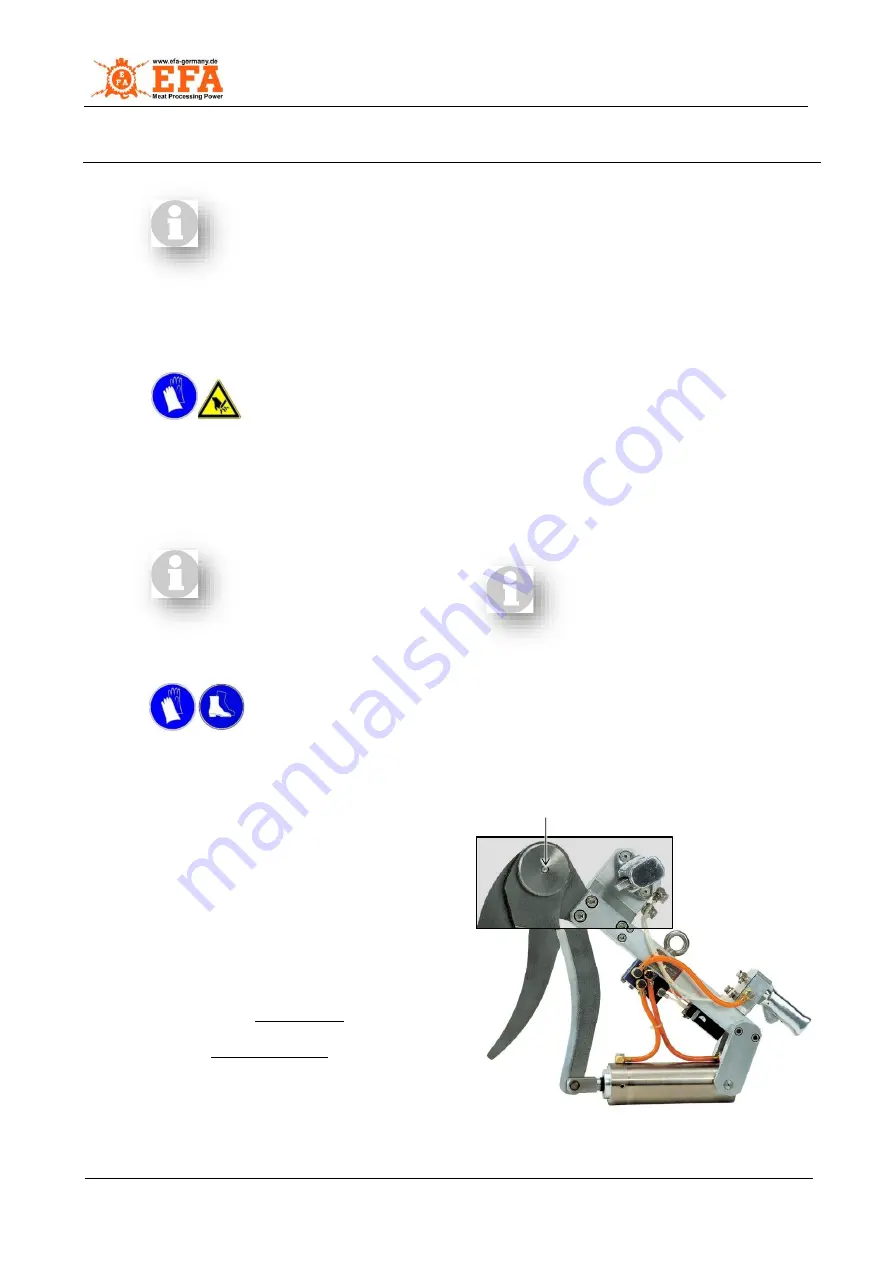

Fig. 7.1

– Lubricating point

7

Service and maintenance

Note!

Observe all safety

instructions.

To ensure the longest possible service life and low wear and tear, the cutter must be checked and serviced

regularly.

Service and maintenance work must only be carried out by instructed personnel.

Only use

genuine spare parts

or spare parts recommended by

Schmid & Wezel GmbH Maschinenfabrik

.

7.1

Daily cleaning after completion of the slaughtering

Trouble-free continuous operation can only be guaranteed if the EFA cutter is kept perfectly and hygienically

clean at all times.

Also observe the safety instructions

in the product data sheets of the

cleaning agents.

Do not use any aggressive solvents!

Do not use a steam blaster or high-

pressure cleaner! Do not immerse the

device in water!

Observe the applicable safety and hygiene requirements for this purpose!

Warning!

Wear protective gloves and

safety shoes when cleaning the

cutter.

To clean the cutter after working with it, use a cloth, brush and warm water (40

– 55 °C). Stubborn or encrusted

dirt must be soaked in cleaning agent. To do this, clean with a cleaning agent that you spread on the surface to

be cleaned and leave to take effect for 15

– 20 minutes.

Subsequently wash off the dissolved soiling manually

with warm water and then dry.

The cutter can also be cleaned with a high-pressure

water jet, but the cylinder seal must not be exposed

to the jet directly.

7.2

Daily maintenance of the cutter

7.2.1

Lubrication

After every cleaning, grease the pivot and sliding

points lightly with EFA special oil.

Grease the blades via the grease nipple (X),

see Fig.

7.1

, using EFA special grease (1

– 2 strokes with

grease gun).

Warning!

Cutting hazard!

Before carrying out any

maintenance work, switch off

the device and disconnect it

from the plant network!