9

en

GB

F

D

E

NL

P

GR

TR

CZ

SK

RUS

UK

PL

H

LV

EST

LT

RO

supplied wrench.

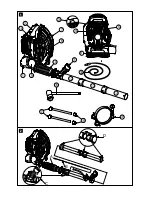

3. Fit the control handle (11, Fig.1) on the

blower tube (12, Fig.1) after fully undoing

the screw located under the locking lever

(Fig.5) using the supplied hex wrench.

Refer to Fig.4:

1. With the locking lever in its lowered

position (locked), tighten the screw

sufficiently to secure the control handle to

the blower tube but without tightening it

fully. Do not tighten the screw with the

lever in the open position.

2. Wind the antistatic cable around the blower

tube in a spiral (B, Fig.2) and insert it into the

hole in the blower tube; connect the end of

the antistatic cable B to the terminal in the

control handle (as shown in circle C, Fig.2).

3. Couple the blower tubes (13-14, Fig.1)

by means of the bayonet fitting (see the

bayonet fitting in the enlarged view in circle

D, Fig.2).

Adjusting the control handle

Correct positioning of the control handle

is extremely important in order to work

comfortably with the blower. To adjust the

control handle position:

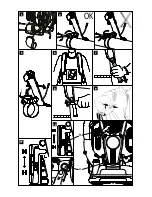

1. Raise the locking lever (1, Fig.5).

2. Find the most comfortable working position

by sliding the control handle and adjusting

its angle.

3. When you find the preferred position, lock

the control handle by lowering the locking

lever.

Adjusting the harness and quick release

WARNING - The harness must be

adjusted with the engine stopped.

Before using the blower it is extremely

important to ensure the weight of the machine

is correctly balanced on your shoulders. This is

done by adjusting the length of the shoulder

straps until the machine is perfectly in contact

with your back and shoulders.

Note that correct balancing of the machine

is especially important when working on

gradients. To tighten the shoulder straps pull as

shown in Fig.7.

To loosen the shoulder straps lift the buckle

with the movement shown in Fig.8.

In the presence of danger, release the

machine from your shoulders by proceeding

as follows:

1. Use one hand to press the quick release tabs

on the right-hand shoulder strap (shown in

the box in Fig.6) as shown in Fig.9.

2. Accompany the machine by bending your

upper body slightly to the left: the blower

will slide off your shoulders.

5. STARTING

FUELING

This product is powered by a 2-cycle engine and

requires pre-mixing gasoline and 2-cycle oil.

Pre-mix unleaded gasoline and 2-cycle engine oil

in a clean container approved for gasoline.

RECOMMENDED FUEL: THIS ENGINE IS

CERTIFIED TO OPERATE ON UNLEADED GASOLINE

INTENDED FOR AUTOMOTIVE USE WITH AN

OCTANE RATING OF 89 ([R + M] / 2) OR HIGHER.

Mix 2-cycle engine oil with gasoline according to

the instructions on the package.

We strongly recommend the use of 2% (1:50)

Efco two cycle engine oil, which is specifically

formulated for all air-cooled two-stroke engines.

The correct oil / fuel proportions shown in the

table are suitable when using an equivalent high-

quality engine oil (JASO specification FD or ISO

specification L-EGD).

CAUTION: DO NOT USE AUTOMOTIVE OIL

OR 2-CYCLE OUTBOARD OIL.

GASOLINE

OIL

2% - 50:1

ℓ

ℓ

(cm

3

)

1

5

10

15

20

25

0,02

0,10

0,20

0,30

0,40

0,50

(20)

(100)

(200)

(300)

(400)

(500)

Summary of Contents for SA 9500

Page 2: ...English 5 Fran ais 20 Espa ol 36...

Page 3: ...1 3 2 11 10 9 12 13 14 7 8 15 4 5 6 16 17 18 19 20 D C A B 1 2...

Page 4: ...OK 1 3 4 6 8 12 5 11 7 9 A B...

Page 5: ...1 2 3 4 RCJ6Y 0 5 mm 0 020 13 15 17 18 19 14 16 4 3 2 1 5...

Page 6: ......

Page 54: ......

Page 55: ......