10

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - +46(0)300 - 22320 - export@effecta.se

Remember that during the first firing the boiler can feel sluggish and tough to fire. This is because

all the metal surfaces in the boiler are clean and cooled against the boiler water, the ceramics also

has some moisture that needs to dry. This uses energy from the wood, so the boiler can feel a bit

sluggish.

During the first firing, there is also a lot of oxygen in the water so it can sound as if it is simmering

in the boiler. This will go away when the system has been heated a few times.

The control switch should always be switched on. Place a handful of finely chopped dry wood at

the bottom of the loading compartment. Then take plenty of paper and place on top of the wood.

- Press button (A / startup) to start the fan and the charging pump, then ignite.

The lower door must be shut and the loading compartment door can be ajar but it can also be

closed. Test the way that suits you best. When the wood has ignited and there is a bed of embers,

the loading compartment can be filled with wood. Start by adding smaller pieces of wood at the

bottom and increase the size the further up in the loading compartment you go. Remember to stack

the wood carefully. It is important to get the best possible effect of the firing. When it has burned for

about 15 minutes, the flame will fill the bowl that you see in the inspection glass in the lower door.

The boiler burns at its best if the combustion is left on its own. It is therefore not appropriate to stir

the in the box during firing. If you open the door during firing, there is a risk of flashover in the box,

with poorer function as a result.

If you burn a lot of dry wood and have a strong draught in the chimney, you may hear a whispering

sound in the air dampers. This does not impair the boiler combustion or function, but to avoid this

you have to install a draft stabiliser that maintains a stable draught in the chimney.

NOTE: In case of a second insertion, there is a small risk of smoke emission. Therefore, wait until

the flue reaches a temperature just above 100°C. Open the door carefully to release any gas and

smoke from the loading compartment if necessary.

▀

The first firing

▀

Firing cycle

Start

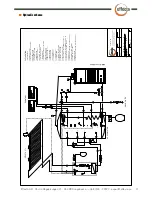

Press the (START) button.

Fan and charging pump start,

the lambda probe is heated.

The dampers are adjusted

to Primary 70 % open and

Secondary 30 % open.

Operating phase

When the flue gas reaches

100°C , the dampers start to

regulate to achieve the set co²

level. The probe detects a value

every 20 seconds and adjusts

when the difference is + / - 0.5

% from the set value. If the co²

level must be increased, the

primary 10 % opens and the

secondary is reduced by 10 %.

If co² levels must be reduced,

the reverse occurs.

Reducing fire

When the co² level goes

down below 8 %, the

secondary damper shuts off

completely. And when the

flue gas temperature is below

90°C, the fan and circulation

pump shut off. The damper

closes completely. In order

to prevent downdrafts.

Safety

If the water jacket overheats

during firing, a protection will

stop the fan electronically

at 95°C. If the temperature

remains high, a mechanical

thermal protection is initiated.

This must be reset manually.

►

►

►

▬