Daily

VUTEk 3r & 5r Series Maintenance Guide

35

The following maintenance tasks must be performed once daily.

PPE Items:

GLOVES NITRILE DISPOSABLE BOX LARGE

SAFETY GLASSES

Required Items:

WIPES 9X9 CLEAN ROOM

How-to Video:

Directions:

NOTE: Even if you are not using the white ink system, you must Purge the two white INK CHANNELS, stir the ink

channels, operate the mixer in the white Main Ink Tank, and perform a 2 second purge on both white ink

channels at least once a day.

NOTE: Print a small WHITE print job at least once a day to maintain the print head quality.

1.

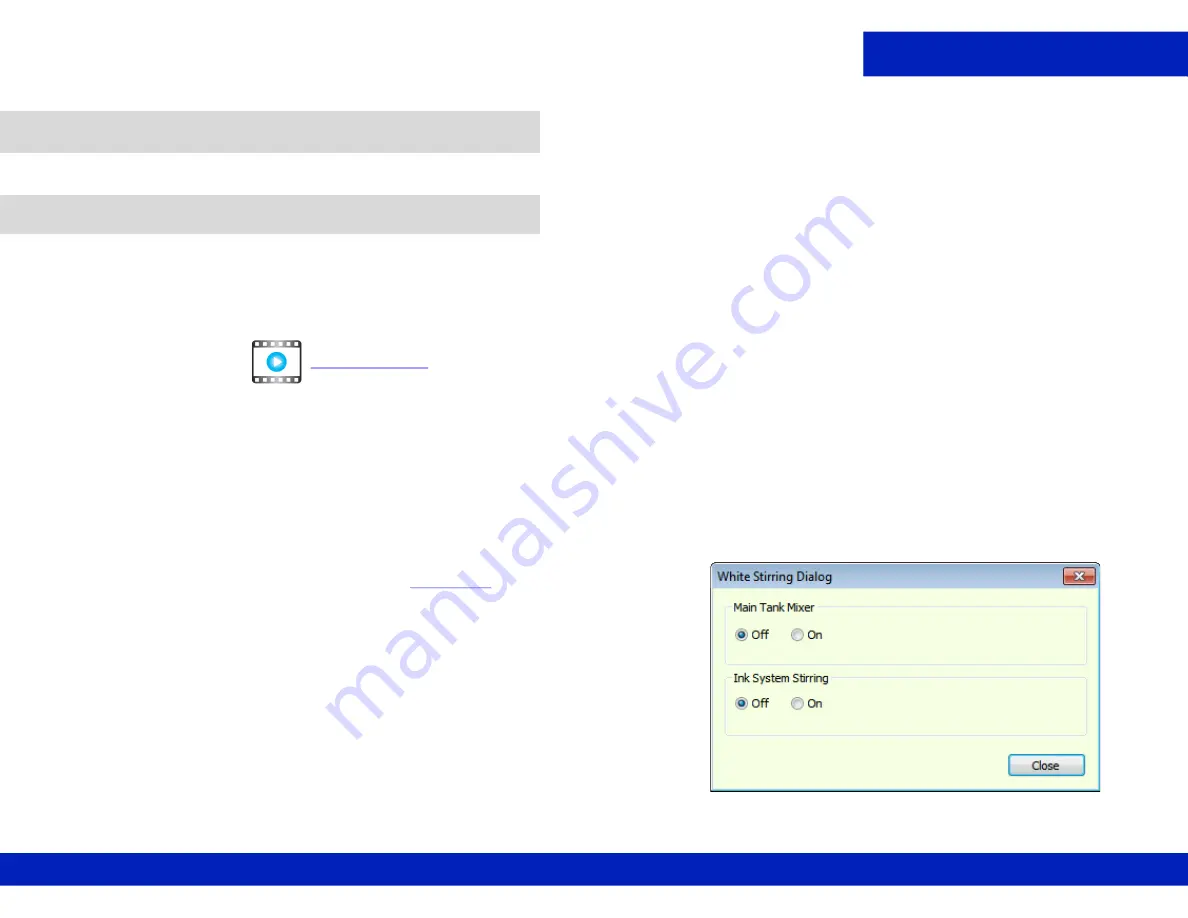

Open the

Tools

tab and select the

White Stirring

option. The

White Stirring

.

2.

Click the

Main Tank Mixer

and the

Ink System Stirring

ON

radio

buttons and click

Close

.

3.

Wait for two minutes and re-open the

White Stirring Dialog

and

click the

Main Tank Mixer

and the

Ink System Stirring

OFF

radio

buttons and click

Close

.

4.

Perform a 2 second Purge on White Channels only.

5.

Dry wipe the White print head faces, allowing the wipe to absorb

excess ink from the print heads.

6.

To make the White Stirring option automatic, open the

PRERENCES

dialog box.

5.0

Once Daily Maintenance

5.1

Perform white ink maintenance.

Figure 5-1 White Stirring Dialog