Settings

EFORT INTELLIGENT EQUIPMENT CO.,LTD

139

model, and then the collision detection function is turned on. If the load data is not

set correctly, or there is too much process force acted on the robot, then false

positives may occur.

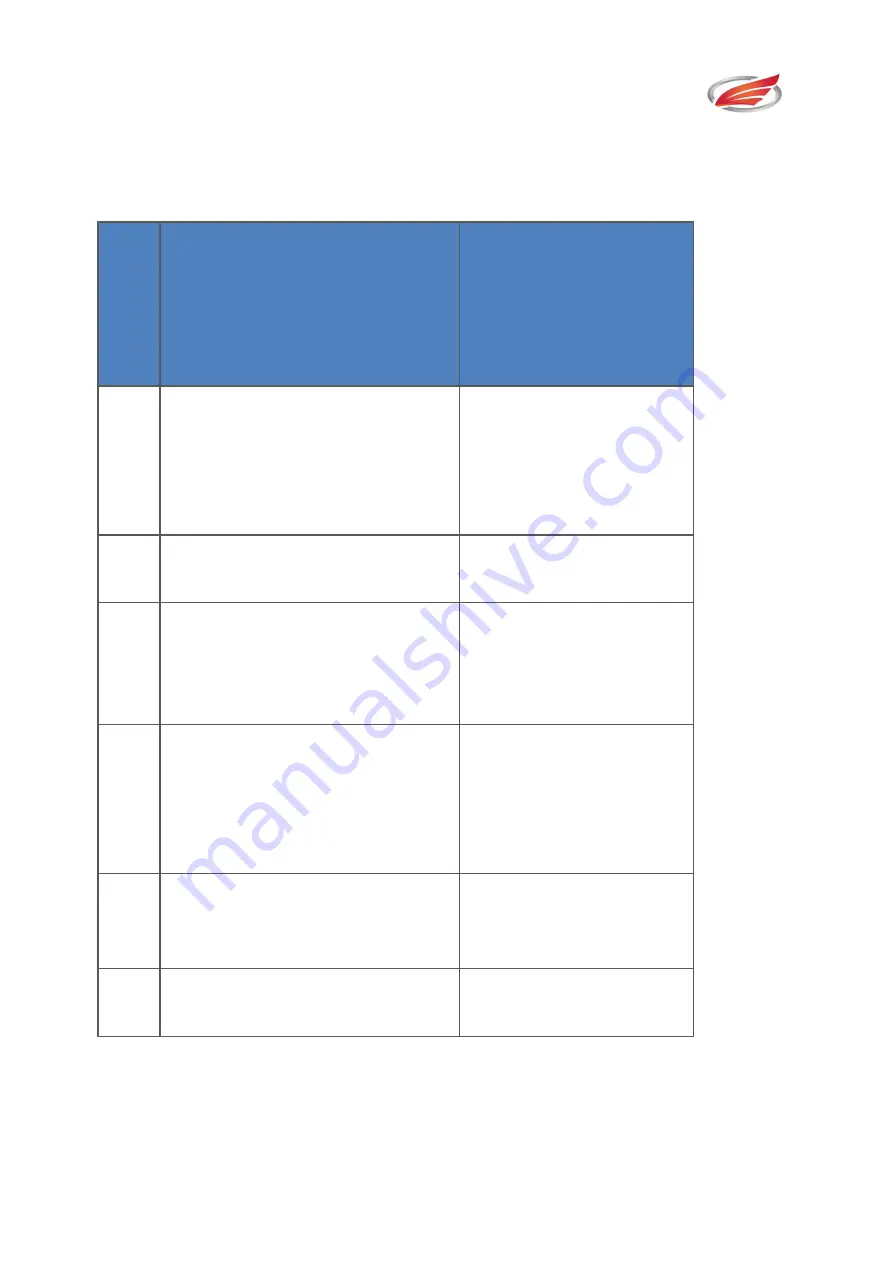

The following are some possible false alarms and recommended solutions:

Nu

m

b

e

r

Abnormal condition

Solution

1

Incorrect setting of tool load

Use the load identificatio

n function to define the

load, or directly enter the

load information manual

ly.

2

The mass or inertia of the load i

s very large

Reduce detection sensitivi

ty.

3

Many external forces are introduc

ed into the process

Reduce the sensitivity of

collision detection at 3

0% intervals until no fals

e positives are generated.

4

There are short-term or temporary

external forces

Use the collision.setCollis

ionPar command to reduc

e sensitivity or turn off t

he collision detection fun

ction.

5

In automatic mode, when the spe

ed is too fast and the sensitivity

is high

Reduce speed or sensitivi

ty.

6

Other false positives

Turn off the collision det

ection function.

Setting

The setting function can only be used in combination with the automatic

operation of the program. Its function is to collect the torque peak of each axis