Mechanical Operations and Maintenance Manual for Industrial Robot ER10-1600

33

Note:

①

fixing screws, four M5×16

;②

adjusting screws, two M5×30

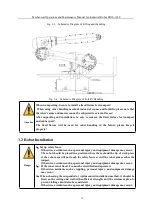

Fig.4-2 J5Axis Timing Belt Structure Diagram of ER10-1600X Robot

Note:

①

fixing screws, four M5×16

;②

adjusting screws, one M5×30

Fig. 4-3 J6 Axis Timing Belt Structure Diagram of ER10-1600X Robot

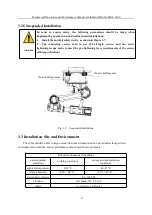

4.4.2 Timing Belt Replacement

The timing belt needs to be replaced every 3 years or every 11520 hours of operation of the robot.

At the same time, customers should pay attention to the appearance of the timing belt every time they

perform maintenance on the timing belt. If the following damage occurs, please replace the timing belt in

time.

Table 4-9 Timing Belt Damage Statistics Table

Excessive wear

Cracks appear

The teeth form are worn

and the rubber is

exposed

The corners are worn

and the core wire is

dropped

teeth root crack

side crack

①

②

①

②

①

②

①

②