Mechanical Operations and Maintenance Manual for Industrial Robot ER10-1600

32

4.3.4 Release the Residual Pressure in the Lubricating Oil Cavity

After the oil is supplied, in order to release the residual pressure in the lubrication tank, the robot

should be properly operated. At this time, install a recovery bag under the lubricant inlet and outlet to avoid

the spilled lubricating oil from scattering.

In order to release the residual pressure, when the oil drain port is opened, the J1 axis is in the range of

± 30 °, the J2 / J3 axis is in the range of ± 5 °, the J4 axis and J6 axis are in the range of 30 ° for more than

20 minutes, and the speed is controlled in the low-speed movement state.

When the above actions cannot be performed due to the surrounding conditions, the robot should be

operated for the same number of times (if the axis angle can only be half, the robot should be operated for

twice the original time). After the above actions are completed, install the sealing screw plug on the oil

drain port (use a combination pad or wrap a sealing tape).

4.

4

Timing Belt Maintenance

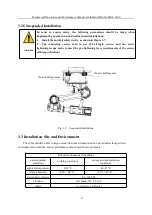

The J5 and J6 axes of the robot are driven by timing belt, which may become loose after running for a

period of time, resulting in the decline of the accuracy of the robot. At the same time, after a long time of

operation, the timing belt may be worn, cracked, etc. If it is not replaced and maintained, it may cause

transmission failure and even economic loss.Therefore, it is necessary to check the running status of the

timing belt regularly (recommended every six months). If it is loose, it should be tensioned in time. If it is

damaged, it should be replaced in time to ensure the transmission accuracy and stability of the timing belt.

4.4.1 Timing Belt Tension

A tension gauge is required for timing belt tensioning. Customers can operate it by themselves or

contact our company's after-sales service personnel.

The standard range of the tension force of the J5 axis timing belt of the ER10-1600 robot is 87±5HZ,

and the standard range of the tension force of the J6 axis timing belt is 130±5HZ. Refer to the standard for

testing and adjustment.The specific operation procedures are as follows:

(

1

)

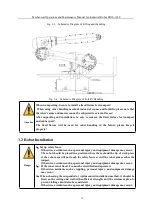

Remove the cover plate of the robot wrist part, and use the timing belt tension gauge to detect the

tension of the J5 and J6 axis timing belts. If the tension is within the standard range, there is no need to

tension and the maintenance ends. If the tension deviates from the standard range, proceed as follows

(

2

)

Loosen the fixing screw of the motor mounting plate until the position can be adjusted left and

right.

(

3

)

Adjust the tension of the timing belt through the adjusting screw of the motor mounting plate, and

use a tension gauge to detect the tension until it meets the standard range.

(

4

)

Tighten the fixing screws of the motor mounting plate, and refer to the appendix standard for

torque specifications.

(

5

)

Properly loosen the adjusting screw, and then tighten the lock nut on the adjusting screw to

prevent the screw from loosening.

(

6

)

Install the cover of the wrist body part, and the maintenance is over.