25

Chapter Four Overhaul and Maintenance

Overhaul is divided into daily overhaul and regular overhaul. Inspectors must prepare overhaul plans

and carry out overhaul. Please refer to the table below for overhaul items and overhaul periods.

In addition, the overhaul must be carried out every 40,000 hours of work or every 8 years (the

principle of choosing which way to reach the deadline first). The overhaul period is based on the handling

operation. Please contact the company service departmentif the inspection and adjustment method is

unclear.

4.1 Preventive Maintenance

Follow the method introduced in this chapter and perform regular maintenance steps to maintain the

best performance of the robot.

4.1.1 Daily Inspection

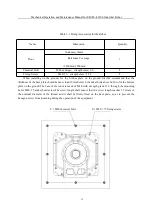

Table 4-1 Daily Inspection

No.

Inspection items

Inspection positions

1

abnormal noise inspection

check whether the transmission mechanism has abnormal

noise

2

interference inspection

check whether the transmission mechanism is running

smoothly and whether there is abnormal vibration

3

air cooling inspection

check whether the fan behind the control cabinet is well

ventilated

4

pipeline accessories inspection

check whether it is complete , whether it is worn or not,

whether there is rust

5

peripheral electrical accessories

inspection

check the external wiring of the robot and whether the buttons

are normal

6

leak inspection

check whether there is lubricating oil leakage on the body

4.1.2 Quarterly Inspection

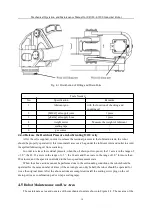

Table4-2 Quarterly Inspection

No.

Inspection items

Inspection positions

1

control unit cable

check whether the teach pendant cable is improperly twisted

2

ventilation unit of control unit

If the ventilation unit is dirty, cut off the power supply and

clean the ventilation unit

3

cables in the mechanical unit

check whether the socket of the mechanical unit is damaged,

whether it is bent abnormally, and whether the servo motor

connector and the circular connector are connected reliably

4

cleaning and overhaul of

various components

check whether there is a problem with the component and

deal with it

5

tightening of external main

screws

tighten the end effector screws and external main screws