Mechanical Operation and Maintenance Manual for ER20-1100 Industrial Robot

19

Chapter 3 Transportation and installation

3.1 Robot transportation

3.1.1 Transportation precautions

See below for transportation precautions. Please fully understand the following content,

and then operate safely.

Transporting robot and control devices must be performed by qualified personnel for

hooking, lifting and forklift, etc. Operators without right skills may cause accidents, such

as tipping and falling.

Please follow the methods recorded in the manual and confirm the weight and procedures

before transporting the robot and control devices. Or accidents, such as tipping or falling

may occur.

Attention should be paid to avoiding the damage of wiring in transporting and installation.

Additionally, protective measures, such as cover the protective shield, should be taken after

the installation to avoid the damage of wiring by operators and forklifts.

3.1.2 Auxiliary handling tooling

Before handling the robot, the robot needs to fix the body part of wrist to prevent the

robot damage from its shaking and collision. A packaging fixation bracket is generally used to

connect the body of wrist and the transposition part.

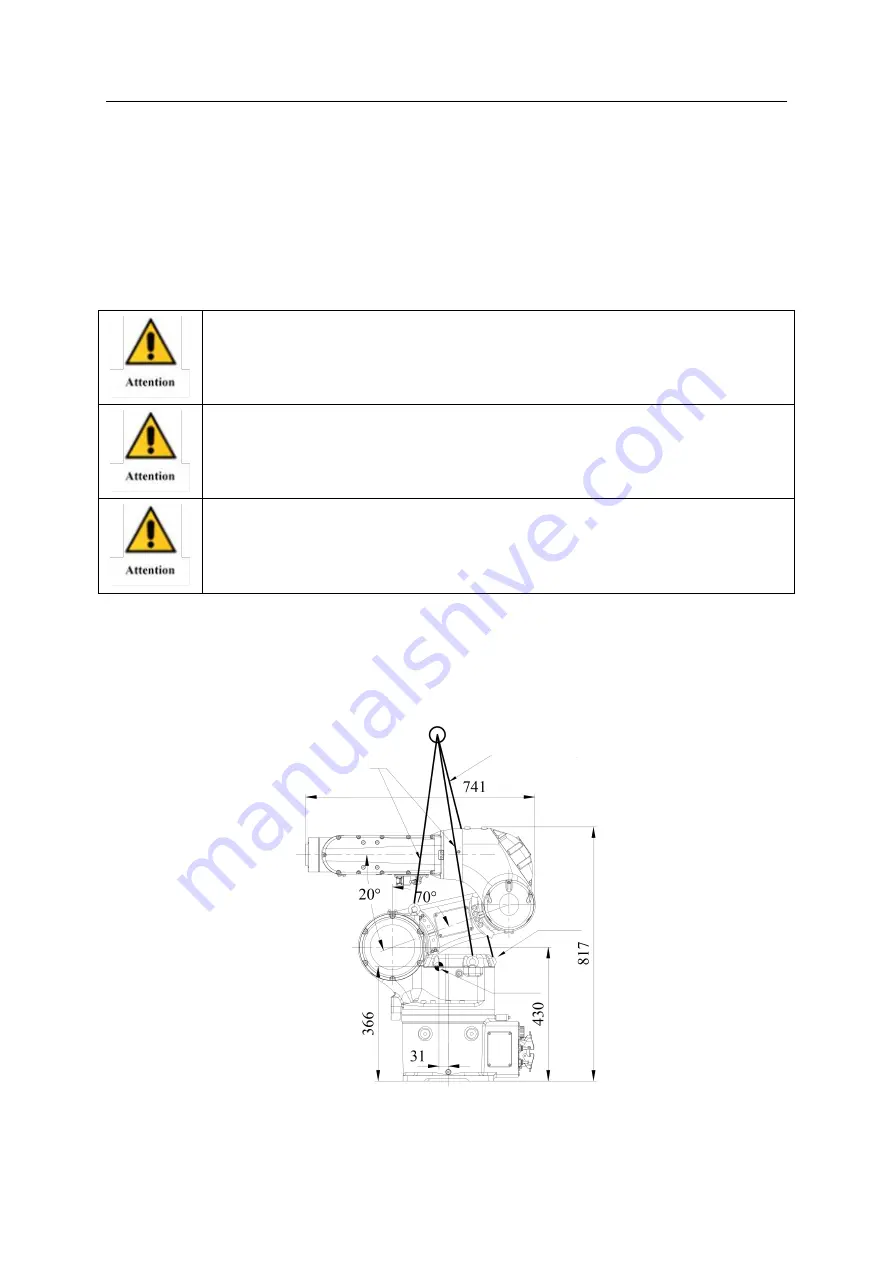

Figure 3-1 Installation schematic of packing and fixing bracket

2 meters length 500kg-load

soft lifting belt × 4

(Do not use steel cable)

Protective soft-pads shall be

added in the part that

contacting with the robot body

lifting ring

screw

M12 × 3

Position of

barycentre