Mechanical Operation and Maintenance Manual for ER20-1100 Industrial Robot

37

1). Maintenance personnel who enter the safety fence must receive professional training.

2). When maintenance personnel enter into the robot’s working area, the robot must be

shut off and locked.

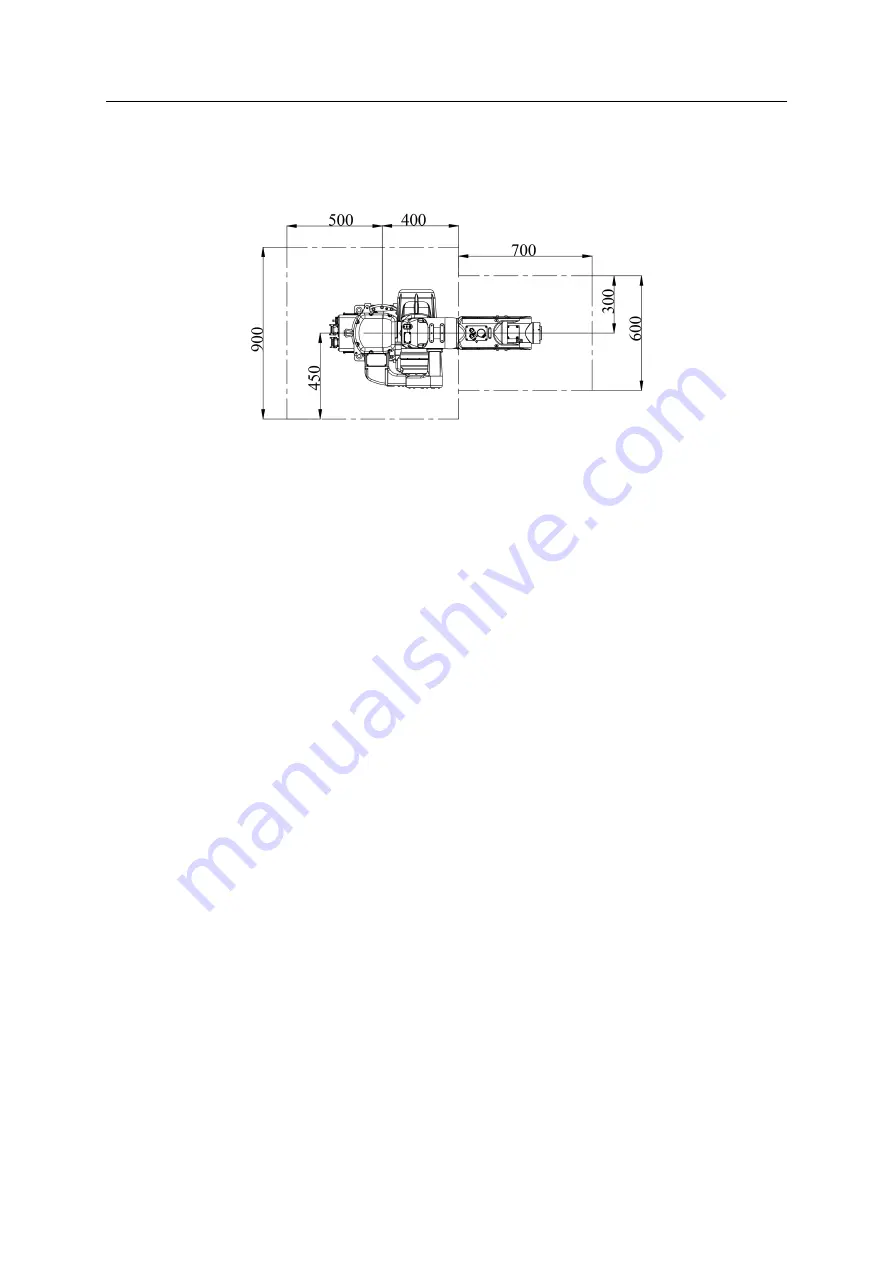

Figure 4-3 Area of maintenance and operation

4.6 Calibration of home position

Calibration is the execution to relate the azimuths of each axis of robot to the values of

encoder. The purpose of calibration of home position is to acquire the values of encoder

corresponding to the home position.

The calibration of home position has been executed before the robot is delivered. So

generally in daily operations, it is no necessary to perform the calibrating operation. But in the

following situation, the calibration of home position is required to perform.

1). The servo motor was replaced.

2). The encoder was replaced.

3). The reducer was replaced.

4). The cables was replaced.

4.6.1 Calibrating method of home position

The calibration of home position is a relatively complex process. Basing on the current

actual situations and the objective conditions, the tools and the methods of calibration of

home position, some common problems, and the ways to solve these problems are introduced

in the following.

1). Calibration of software home position

A laser tracker needs to be used to establish the coordinate system of each joint of the

robot and the system encoder’s reading is set to zero. The calibration of software is

complicated, so it is required for professional personnel of our company to perform.

2). Calibration of hardware (mechanical) home position (mark alignment)

Rotate the mark block to align the home position line, the hardware (mechanical)

calibration is completed.

Maintenance area

Calibration area