Mechanical Operation and Maintenance Manual for ER20-1100 Industrial Robot

44

Appendices

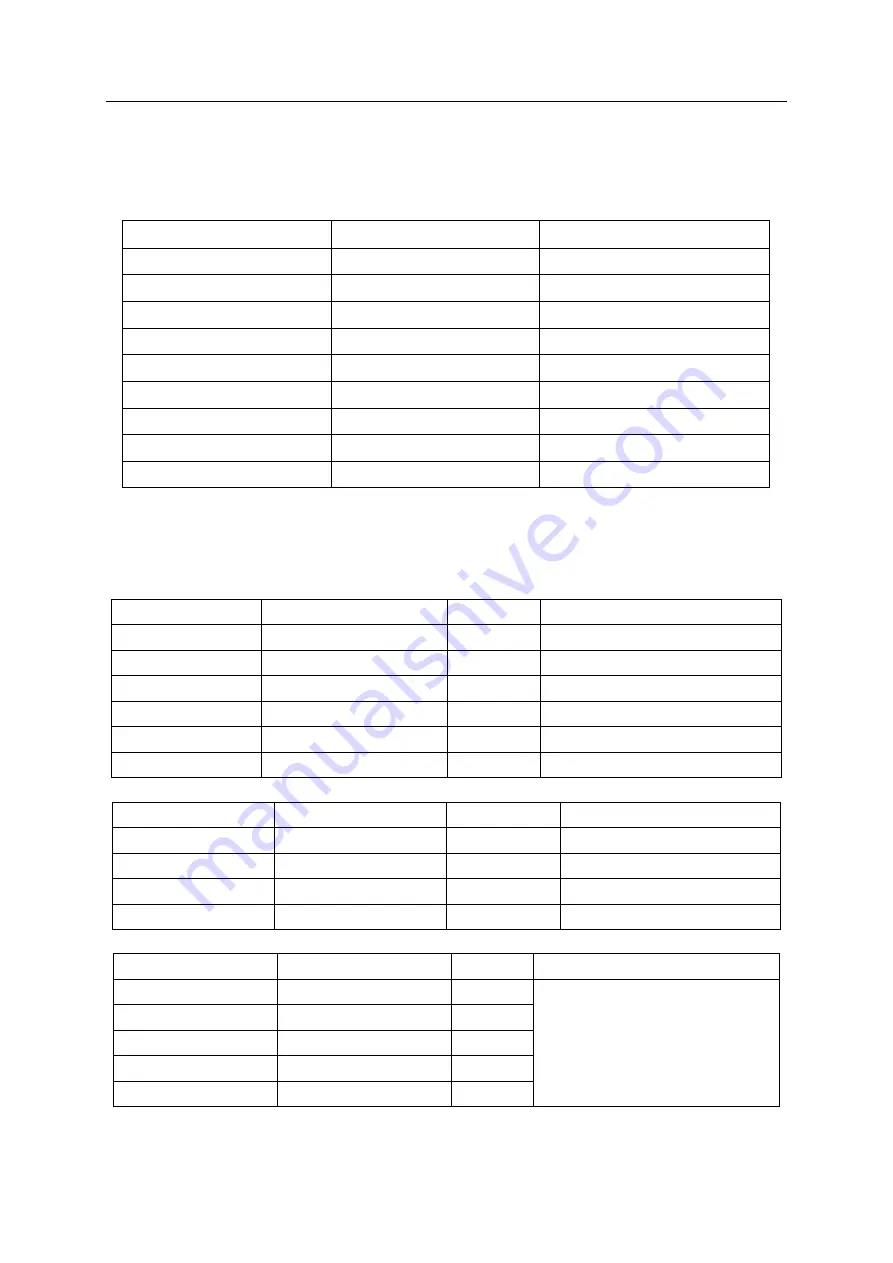

A Torque table of tightening screw

Note

:

Because the motor flange has special material properties, the tightening torque cannot be too high.

Please refer to the table.

B List of Spare Parts

Table1 Servo Motor

Name

Material number

Unit per

robot

Remark

Servo motor

/

6

J1 input gear

/

1

J2 input gear

/

1

J3 input gear

/

1

J4 input gear

/

1

J4 output gear

/

1

Table2 Rubber Seal, Plug screw, and Others

Name

Specifications

Unit per robot

Applied position

O-ring rubber seal

103x3.55

2

O-ring rubber seal

AS568-263

1

Hexagon socket cap plug

screw

M10x1

10

Whole

Composite sealing washer

10

10

Whole

Table3 Sealant and Others

Name

Specifications

Unit per

robot

Applied position

Grease

MOLYWHITE RENO.00

2.5kg

Flat sealant

THREEBOND 1110F

1

Thread locker

THREEBOND 1374

1

Detergent

THREEBOND 6602T

2

Thread sealant

LOCTITE577

1

Screw 12.9 grade

Tightening torque (cast iron)

Tightening torque (cast aluminum)

M3

2±0.18

2±0.18

M4

4.5±0.33

4±0.33

M5

9.01±0.49

7.35±0.49

M6

15.6±0.78

12.4±0.78

M8

37.2±1.86

30.4±1.86

M10

73.5±3.43

59.8±3.43

M12

128.4±6.37

104±6.37

M14

204.8±10.2

180±10.2

M16

318.5±15.9

259±15.9