Mechanical Operation and Maintenance Manual for ER20-1100 Industrial Robot

31

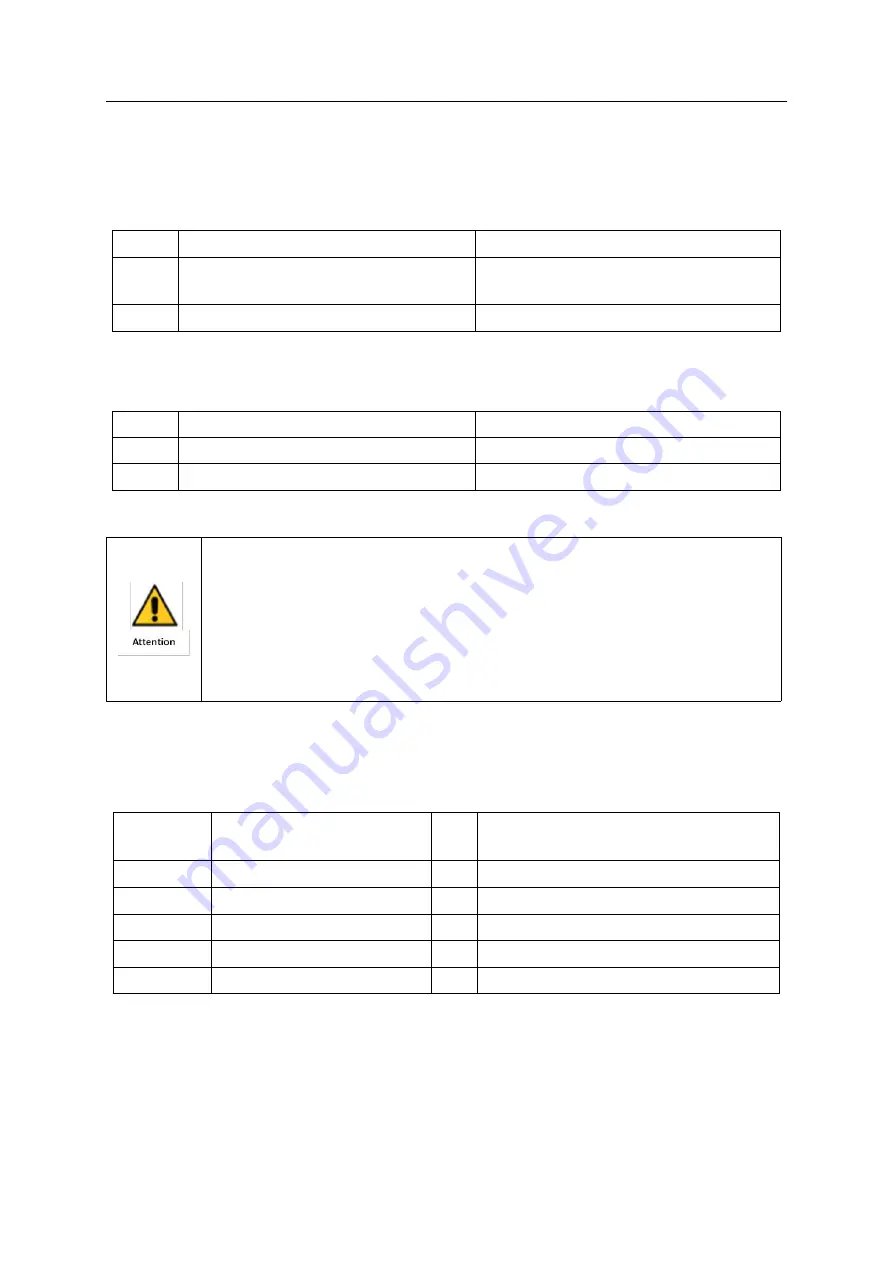

4.1.3 Annual check

Table 4-3 Annual Check

Number

Item

Essentials of checking

1

cleaning, repair, and maintenance of each

component

Check whether problems exist in components and

handle them.

2

tighten external main screws

Tighten the external main screws.

4.1.4 Every three-year check

Table 4-4 Every three-year check

Number

Item

Essentials of checking

1

replace lubricant in the reducer and gear box

replace lubricant according to requirements

2

replace lubricant in the wrist parts

replace lubricant according to requirements

Note:

1

)

The cleaning mainly involves oil seal of the mechanical wrists, chips, and splashes.

2

)

The screws on the end executor and robot body for installation need to be tightened.

Screws removed for repair and maintenance and all the external screws exposed also

need to be tightened. Please refer to the screw tightening torque table in the appendix for

installation torque and paint corresponding glue or sealant.

4.2 Repair and maintenance for main bolts

Table 4-5 The main parts needing bolts check

Number

Check part

Numbe

r

Check part

1

for robot installation

6

for installation of J5 axis servo motor

2

for installation of J1 axis servo motor

7

for installation of J6 axis servo motor

3

for installation of J2 axis servo motor

8

for wrist parts installation

4

for installation of J3 axis servo motor

9

for end load installation

5

for installation of J4 axis servo motor