Mechanical Operation and Maintenance Manual for ER20-1100 Industrial Robot

32

When the bolts need tightening and replacing, a torque wrench must be used to properly

tighten, and then fix the bolts by paint coating. Besides, unloosened bolts are forbidden

to be tightened with torque that higher than required.

4.3 Change lubricant

The robot needs to replace the lubricant every 11,000 hours or every 3 years (taking the

shorter interval between the both).The information or process that the capacity of lubricant

required for each axis, the azimuth of each axis when filling the lubricant, the steps of

replacing the lubricant, are refer to the contents of this section. If you have any questions, or

need technical support, please contact our after-sales service department timely.

4.3.1 Demand capacity of lubricant

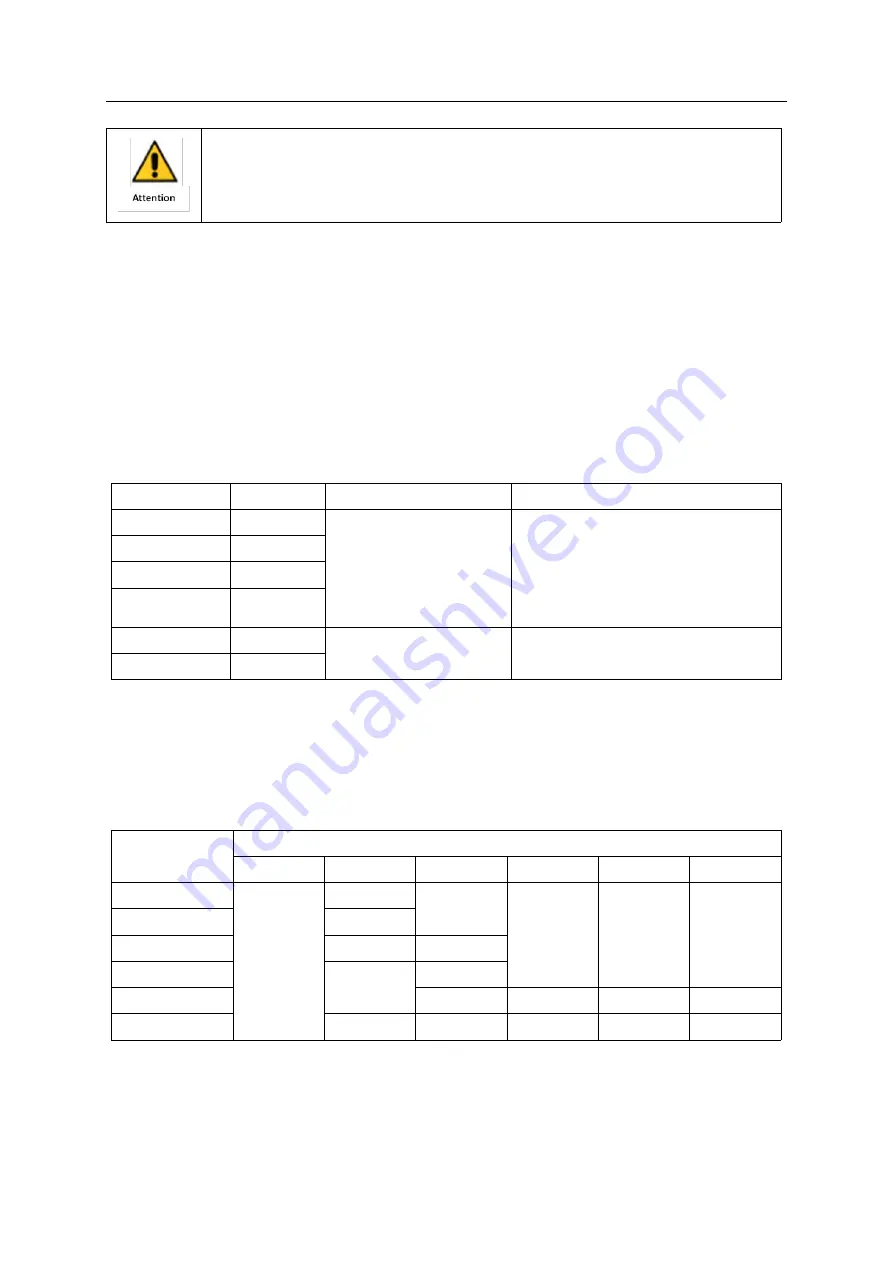

Table 4-6 Capacity table of lubricant to be replaced

Position

Capacity

Lubricant name

Remark

Reducer of J1 axis

600cc

MOLYWHITERE No.00

Rapid injection will cause pressure rising in

the lubricant tank, and then the lubricant will

leak due to cracking of sealing ring.

Therefore, injection speed should be

controlled lower than 40cc/10 seconds.

Reducer of J2 axis

525cc

Reducer of J3 axis

370cc

Cavity of J4 axis

55cc

Reducer of J5 axis

57cc

LD super No.096

Fill with grease when installing the reducer.

Reducer of J6 axis

45cc

4.3.2 Azimuth of axis when lubricant to be replaced

It is recommended to refer to the table as follows for lubricant replacement or

supplement.

Table 4-7 Azimuth of each axis when lubricant to be replaced or supplied

Position

Azimuth

J1

J2

J3

J4

J5

J6

Reducer of J1 axis

Any

Any

Any

Any

Any

Any

Reducer of J2 axis

0°

Reducer of J3 axis

0°

0°

Cavity of J4 axis

Any

0°

Reducer of J5 axis

0°

0°

0°

0°

Reducer of J6 axis

Any

Any

0°

90°

Any

4.3.3 Process for replacing lubricant in J1~J4 axes reducer and wrist part

1). Adjust the robot to the suitable gesture for lubricant filling, according to azimuth