Mechanical Operation and Maintenance Manual for ER20-1100 Industrial Robot

35

to ensure the transmission precision and stability of the timing belt.

Since the J5 and J6 axes are driven by timing belt, so the belt would probably loosen

after operation keeping on a period of time, witch would cause decline of robot precision.

Further more, after a long-time operation, the timing belt may appear wear, cracking or others

conditions. Without replacement or maintenance, it may lead to transmission failure, and even

economic losses. Therefore, it is recommended to check the running state of the timing belt

regularly (every half year suggested). To ensure the transmission precision and stability of the

timing belt, it is suggested that promptly tighten the loosened parts and replace the damaged

parts.

4.4.1 Tightening the timing belt

Customers can use a tensioner to adjust the timing belt, or contact our after-sale service

personnel. The parameters of adjusting operation are refer to table 4-9 as follows.

Table 4-9 Reference of tension and frequency when tightening the timing belt

Tension

(

N

)

Tensioning frequency

(

Hz

)

Timing belt

80

(

1±3%

)

Axis J5

:

115

See the operation steps as follows:

1). Remove the cover plate on both sides of the wrist parts. Check the tension of J5 axis

by using a timing belt tensioner. If it is within the standard range, the maintenance is

completed. Otherwise, continue the operation according to the steps as follows.

2). Release the fixing screws on the motor mounting plate, to be adjusted the left and

right position.

3). According to the tension detection of tensioner , adjust the tension of the timing belt

through the adjusting screw of the motor mounting plate, until the tension value is satisfied

with standard range.

4). Refer to the appendix to choose tools with satisfied torque specifications, and then

tighten the fixing screws on the motor mounting plate by the tools.

5). Loosen the adjusting screw appropriately, then tighten the locking nut on the

adjusting screw to prevent the screw from loosening.

6). Install the cover plate of the wrist part back, and the maintenance is completed.

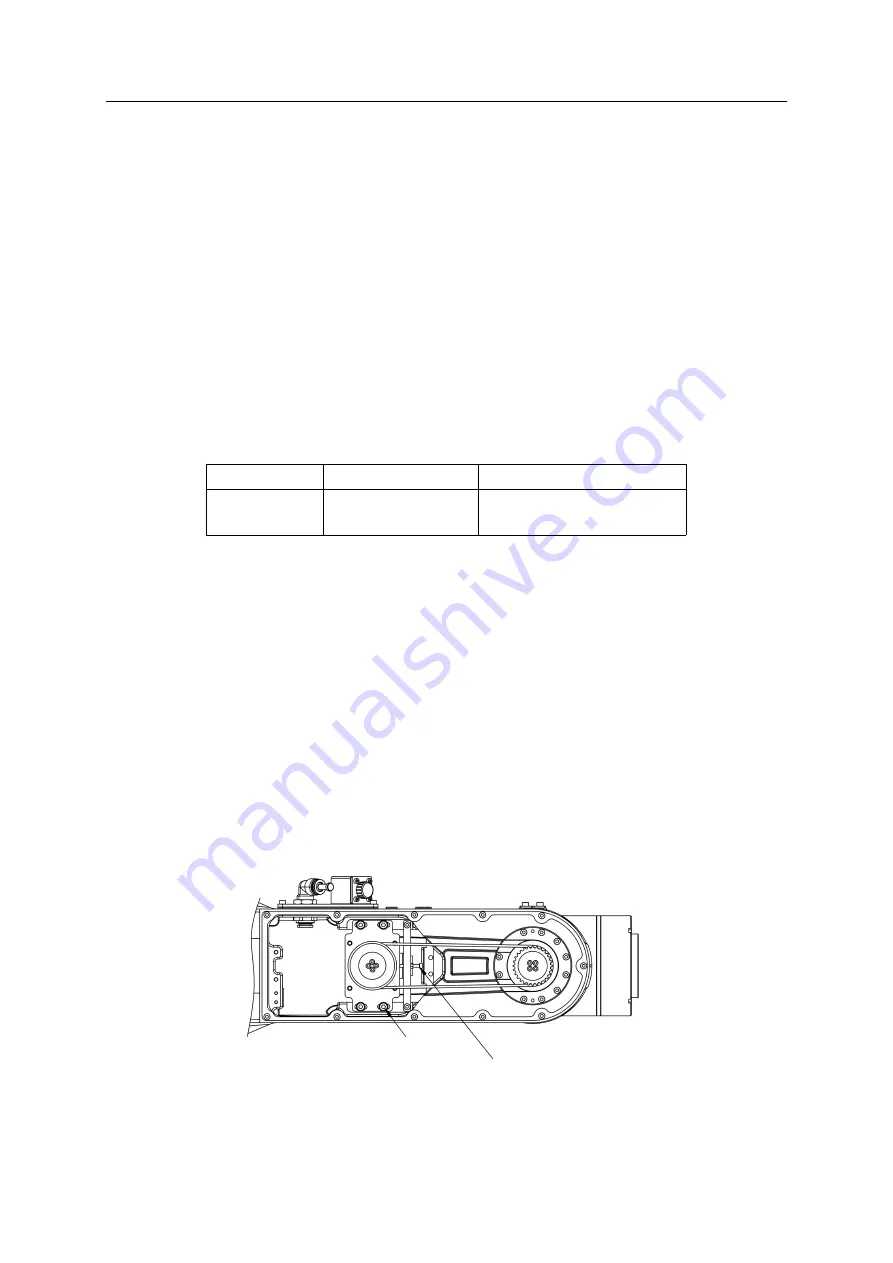

Figure 4-2 The structure of timing belt of axis J5 of ER20-1100 robot

Fixing screws ×4, with the

specification of M5×16 (M5

flat washers are required)

Adjusting screws ×1, with the

specification of M3×22