Mechanical Operation and Maintenance Manual for ER20-1100 Industrial Robot

36

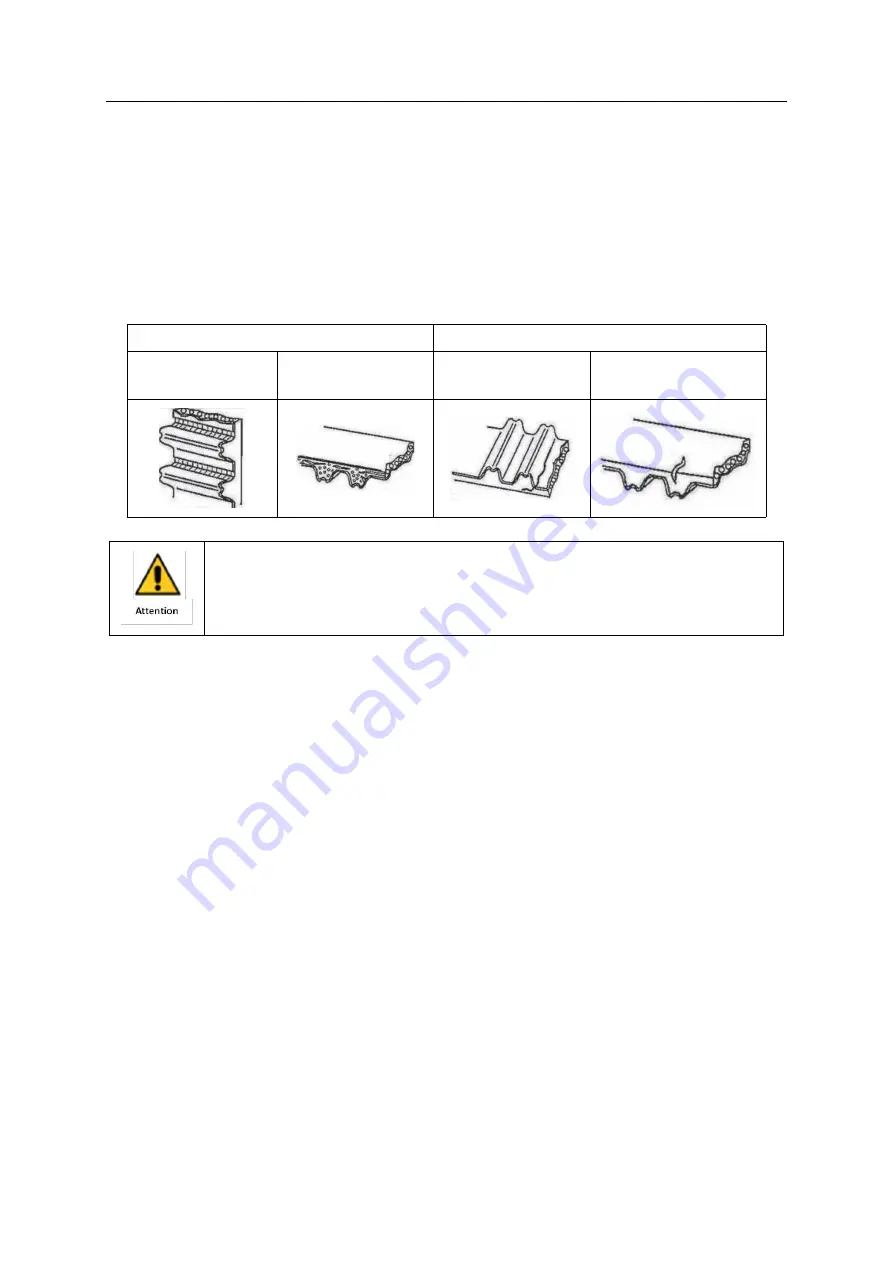

4.4.2 Replacement of timing belt

Timing belts need to be replaced every three years or every 11520 operation hours.

It is noted that during the maintenance, the appearance and condition of timing belt needs

to be checked. If there is damaged, please replace the timing belt in time.

Table 4-10 The damage statistics table of timing belt

Excessive wear

Cracking

The belt teeth worn,

the rubber exposed

The belt corners worn,

the wire cores dropped

The root of belt tooth

cracked

The belt side cracked

The replacement of timing belt involves disassembly gesture of the robot, timing belt

selection, and zero position calibration after replacement. Additionally, special tools

should be used in disassembly. Therefore, potential risks exist if users disassemble them.

Please contact our service department for replacement.

4.5 Robot maintenance and working area

Figure 4-3 shows the maintenance and working area of the mechanical unit. Users can

adjust the working area according to the actual environment.

4.5.1 The safety conditions required for working area

1). Safety fence and safety door must be installed around the robot. If the safety door is

closed, operators cannot go through the safety fence and into the working area. The safety

door should be equipped with a interlock switch, safety latch, etc.. Once the safety door is

open, the robot stops working.

2). The safety carpet or photoelectric switches should be set on the floor, to ensure the

safety of operators. When operators enter into the working space of robot, alarms will be sent

from buzzers or photoelectric switches, and the robot will be stopped.

3). The height of safety fence shall not be less than 2 meters.

4.5.2 Qualification requirements for maintenance personnel and

precautions