Mechanical Operation and Maintenance Manual for ER20-1700 Industrial Robot

31

For screws tightening and replacement, a torque wrench must be used to properly

tighten and paint them. Besides, unloosened bolts cannot be tightened with a torque

higher than required.

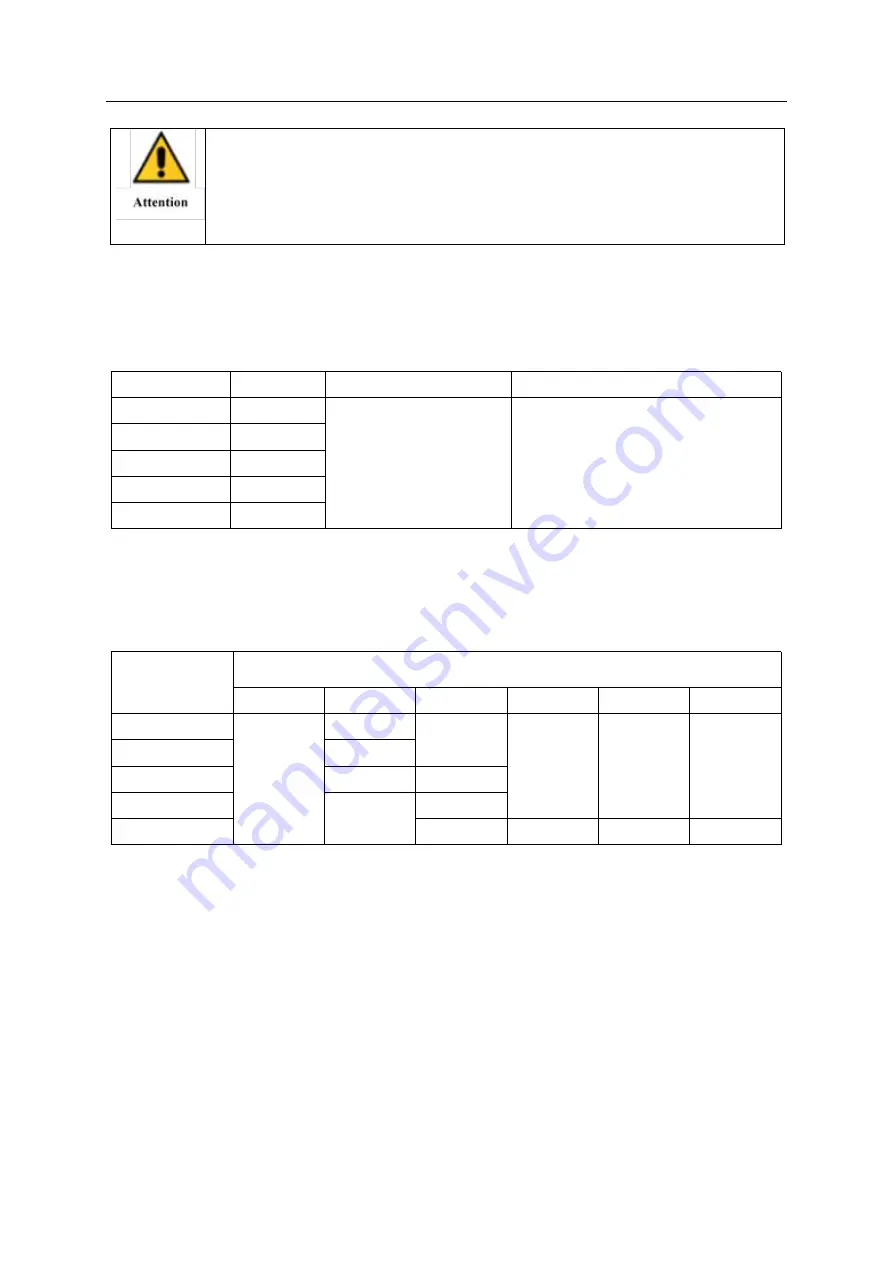

4.3 Change Lubricant

4.3.1 Lubricant Supply Quantity

Table 4-6 Amount of Lubricant to be Changed

Position

Amount

Lubricant Name

Remarks

J1 axis reducer

1310cc

MOLYWHITERE No.00

Quick injection can cause rising

pressure in the tank and crack of the

sealing ring, which lead to lubricant

leak. Therefore, injection speed should

be controlled under 40cc/10 seconds.

J2 axis reducer

1000cc

J3 axis reducer

320cc

J4 axis reducer

125cc

wrist parts

140cc

4.3.2 Lubrication Position and Angle

It is recommended to refer to the table below for lubricant replacement or supplement.

Table 4-3

Angle of Each Axis in lubricant Injection

Position

Angle

J1

J2

J3

J4

J5

J6

J1 axis reducer

any

any

any

any

any

any

J2 axis reducer

0°

J3 axis reducer

0°

0°

J4 axis reducer

any

0°

wrist parts

0°

0°

0°

0°

4.3.3 Procedures for Lubricant Change in J1~J4 Axis Reducer and

Wrist Parts

1

)

Move the robot to the lubrication position as described in table 3.7.

2

)

Cut off power.

3

)

Remove the M10*1 hexagon head plug of the lubricant inlet and outlet ports, as shown in Fig. 4-1.

4

)

Inject new lubricant until it drains from the outlet port.

5

)

Install the hexagon head plugs on the inlet and outlet ports.

6

)

Release the residual pressure in the cavity after injection according to the procedures in 4.3.4.

Incorrect operation may increase internal pressure in the cavity and damage the sealing part, which

lead to lubricant leak and malfunction. Therefore, please follow the steps below to apply lubrication.