Quick Operation Manual for ER3-600 Industrial Robot (EC2-S electric cabinet)

21

3.2 Robot Power Cable, Signal Cable and Ground Wire

A standard delivery should include the robot power cable, signal cable and ground wire cables and the

connection between the robot body and the control cabinet can be completed upon request.

Cable Type

Remarks

Robot power cable

Transfer the driving power from the driving device in the control cabinet to

the robot motor.

Robot signal cable

Transfer the data from the encoder to the serial measurement circuit of the

driver.

Robot ground wire cable

Connect the robot body and the control cabinet.

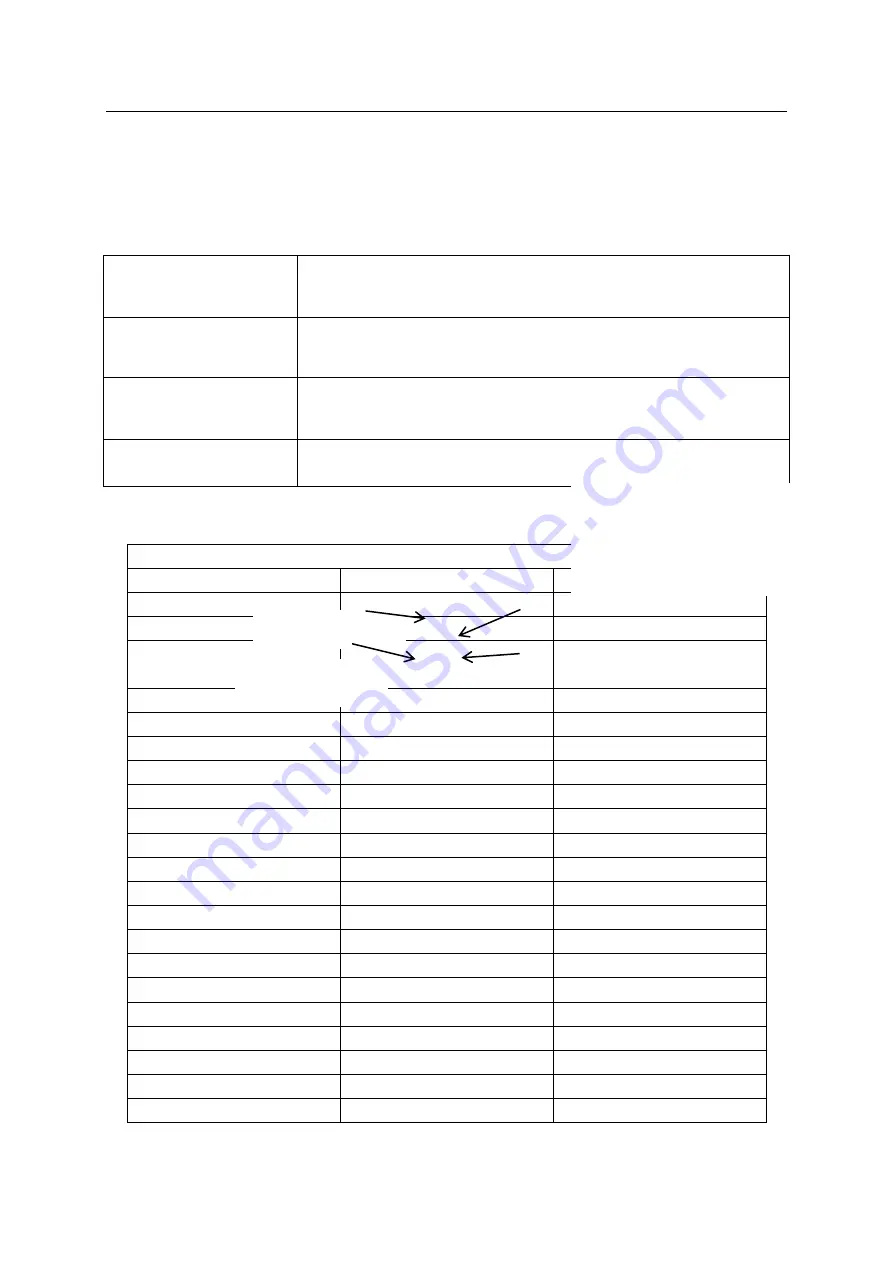

3.3 Definition of Controller Local IO

Table 3-1 Output Ports Description

Output

IO Sequence of Teach Pendant

External Terminal Sequence

Remarks

DO0

\

system occupied

DO1

\

system occupied

DO2

\

Servo confirmed

(

system

occupied

)

DO3

\

system occupied

DO4

\

system occupied

DO5

\

system occupied

DO6

\

system occupied

DO7

\

system occupied

DO8

27

user-defined

DO9

28

user-defined

DO10

29

user-defined

DO11

30

user-defined

DO12

31

user-defined

DO13

32

user-defined

DO14

33

user-defined

DO15

34

user-defined

DO16

35

user-defined

DO17

36

user-defined

DO18

37

user-defined

DO19

38

user-defined

DO20

39

user-defined

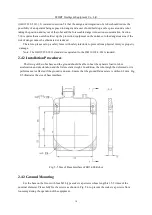

X20 power circular socket

X30encoder signal cable circular socket

PE ground wiring screw

Cable glands*4

Reserved ports *2

Summary of Contents for ER3-600

Page 2: ......

Page 4: ......

Page 54: ...EFORT Intelligent Equipment Co Ltd 48 Fig 4 10 Main Power Switch...