ER7-700 Industrial robot mechanical maintenance manual

27

4.1.3

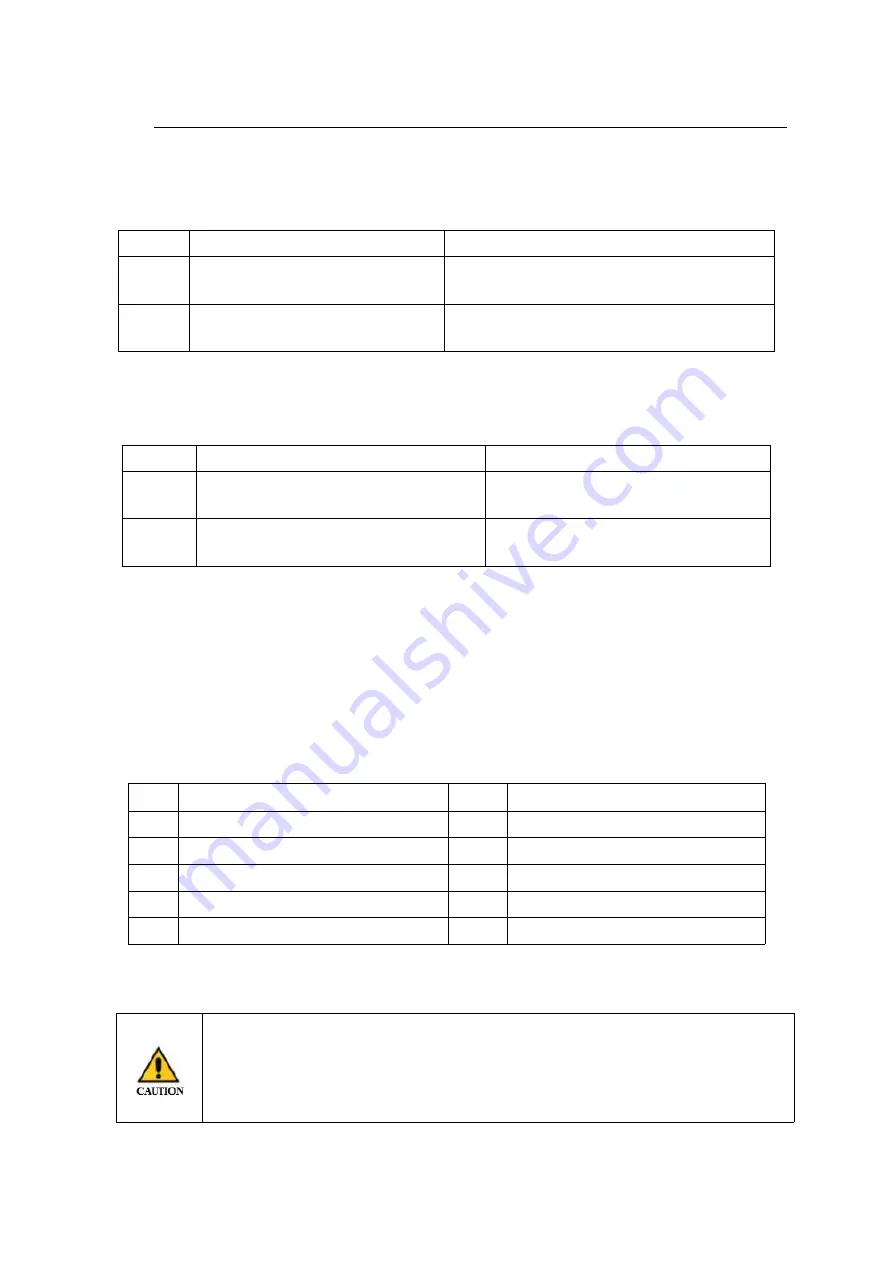

Annual inspection

Table 4-3 Annual Checklist

No

Check item

checking point

1

Cleaning and maintenance of various

components

Check if there is a problem with the part and deal

with it

2

Fastening of external main screws

Tighten the end effector screws and external

main screws

4.1.4

Check every 2 years

Table 4-4 Checklist every 2 years

No

Check item

checking point

1

Replace the lubricating oil of reducer and

gear box

Replace according to lubrication

requirements

2

Change the lubricant of wrist parts

Replace according to lubrication

requirements

Notes:

1) Regarding the cleaning parts, mainly the mechanical wrist oil seals, cleaning chips and splashes.

2) Regarding the tightening parts, tighten the end effector mounting screws, the robot body

mounting screws, and the screws removed due to maintenance, etc. All screws exposed outside

the robot should be tightened. For the installation torque, please refer to the appendix screw

tightening torque table. And apply the corresponding fastening glue or sealant.

4.2

Overhaul of main bolts

Table 4-5 Main screw inspection locations

No

Check parts

No

Check parts

1

For robot installation

6

For installation of J5 axis servo motor

2

For installation of J1 axis servo motor

7

For installation of J6 axis servo motor

3

For installation of J2 axis servo motor

8

For mounting wrist parts

4

For installation of J3-axis servo motor

9

For end load installation

5

For installation of J4 axis servo motor

To tighten and replace the screws, you must use a torque wrench to tighten them with

the correct torque, and then fix them with paint. In addition, it should be noted that

the bolts that are not loose cannot be tightened with a torque greater than the

required torque.