CORDLESS CHAIN SAW — CS1800E

7

EN

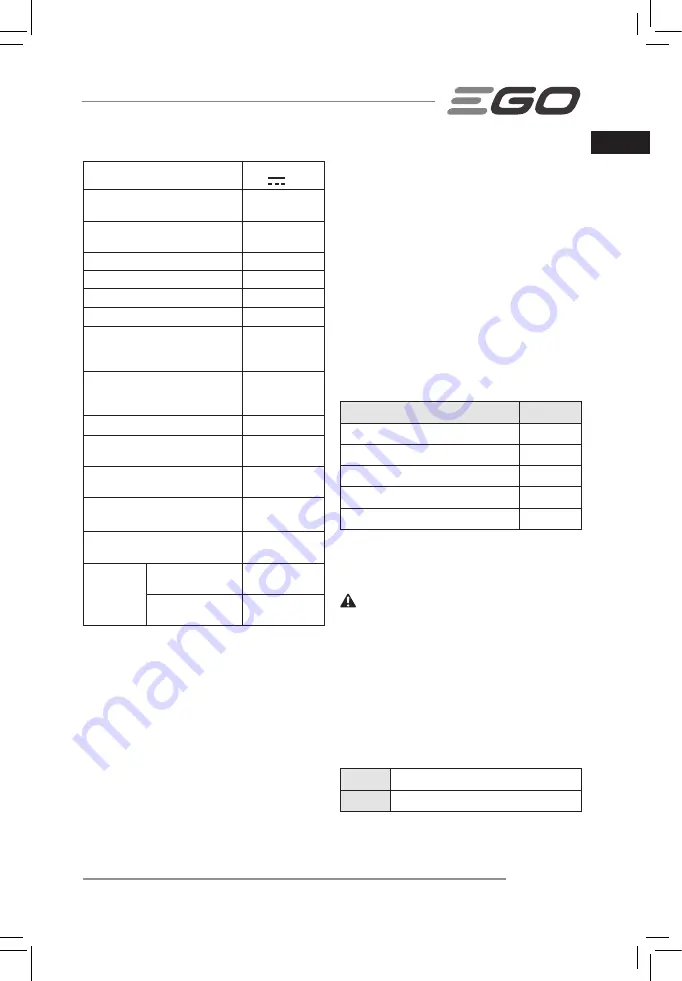

SPECIFICATIONS

Voltage

56 V

Recommended Operating

Temperature:

-15°C-40°C

Recommended Storage

Temperature:

-20°C-70°C

Optimum Charging Temperature

5 °C-40 °C

Chain speed

20 m/s

Chain Pitch

9.5 mm

Chain Gauge

1.3 mm

Saw Chain Type

91PX062X

90PX056X

90PX052X

Guide Bar Type

180SDEA041

164MLEA041

144MLEA041

Chain Oil Tank Capacity

200 ml

Weight

(without battery pack, chain sheath)

4.4kg

Measured sound power level L

WA

103.53 dB(A)

K=1.17 dB(A)

Sound pressure level at working

position L

PA

92.53 dB(A)

K=3.0 dB(A)

Guaranteed sound power level L

WA

(according to 2000/14/EC)

105 dB(A)

Vibration a

h

Front Handle

5.158 m/s

2

K=1.5 m/s

2

Rear Handle

5.537 m/s2

K=1.5 m/s2

◾

The declared vibration total value has been measured

in accordance with a standard test method and may be

used for comparing one tool with another;

◾

The declared vibration total value may also be used in

a preliminary assessment of exposure.

NOTICE:

The vibration emission during actual use of the

power tool can differ from the declared value in which the

tool is used; In order to protect the operator, user should wear

gloves and ear protectors in the actual conditions of use.

DESCRIPTION

KNOW YOUR CHAIN SAW (Fig. 1)

1. Lubricating Hole

2. Guide Bar

3. Saw Chain

4. Oil Tank Cap

5. Chain Kickback Brake Handle

6. Front Handle

7. Battery- Release Button

8. Lock-off Button

9. Variable-Speed Trigger Switch

10. Electric Contacts

11. Ejection Mechanism

12. Oil-Inspection Window

13. Rear Handle

14. LED Button

15. LED Headlights

16. Bucking Spikes

17. Quick Chain-tension Adjust Knob

18. Side Cover

19. Chain Sheath

PACKING LIST

PART NAME

QUANTITY

Chain saw power head

1

Saw chain

1

Guide bar

1

Chain sheath

1

Operator’s manual

1

ASSEMBLY

ASSEMBLING/REPLACING THE BAR AND CHAIN

WARNING:

Adjust the chain-kickback brake handle

in the braking position before assembly.

1. Position the chain saw power head on its side with the

side cover facing upwards (Fig. 2).

2. Remove the side cover by turning the quick chain-

tension adjust knob counterclockwise

3. Lay the new saw chain in a loop on a flat surface and

straighten any kinks .

4. Place the chain drive links into the guide bar groove

and make the chain a loop at the back of the guide bar

(Fig. 3).

3-1

Chain Drive Links

3-2

Guide Bar Groove

5. Hold the chain in position on the guide bar and place the

loop around the sprocket of the power head (Fig. 4).

Summary of Contents for CS1800E

Page 1: ...56 CS1800E BRUSHLESS...

Page 2: ...5 8 7 6 9 10 11 12 13 1 2 3 4 18 19 15 16 17 14 1 2 BRUSHLESS 3 3 1 3 2...

Page 3: ...5 6 7 9 10 4 45 11 BRUSHLESS 8 11 1...

Page 4: ...13 14 15 17 18 12 19 16 12 1 12 2 12 3 12 4 1 1 2 2...

Page 5: ...21 20 20 1 20 2...

Page 6: ...13 BG CS1800E 180SDEA041 500mm XX V min 1 CE...

Page 9: ...16 BG CS1800E 4 8 9 10 11 11 1 1 3 12 50 12 3 12 1 12 3 12 2 12 4...

Page 10: ...17 BG CS1800E 13 14 15 1 3 16 1 3 2 3 17 1 2 18 3 4 19...

Page 11: ...18 BG CS1800E 20 1 21 20 2 WEEE...

Page 12: ...19 BG CS1800E 67 C 67 C EGO...

Page 13: ...20 BG CS1800E EGO egopowerplus com EGO...

Page 15: ...EGO Power EGO Power 02 955 9074 0878 709730 email info instra parts com www egopowerplus bg...