(18)

After rinsing, insert the second (and third) medium container as well, ensuring that the pipe

openings are aligned and safely connected by the rubber seals. Retract all handles and make sure

that all media containers lie flush on top of each other. Attach second and third rubber seals to rele-

vant media container above.

(19)

Then place the white filter pad

on

the top container in such a way that it rests on top of the

retracted handle.

Attention:

The white pad must not lie under the handle, the cut-out for the pipe opening must

remain free.

Place lattice screen on top (cut-out over pipe opening).

Note:

If additional filtering with active carbon is intended, the active carbon sponge (order no.

2628260) is placed under the handle in the top container. The white filter pad is the last layer over

the retracted handle of the container.

Closing filter, inserting adapter.

(20)

Check that the sealing gasket of the filter head fits exactly and remove any soiling. Place head

on filter canister, ensuring that the hose joint of the filter head is inserted into the hose duct of the

media containers. Close all four EZ clips.

(21)

Then place adapter onto the joints (locking bar to the front) and push the lever towards the

adapter as far as it will go. This pulls the adapter into its sealing and at the same time opens it

automatically.

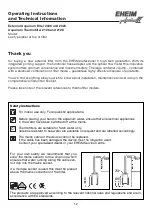

Start-up

(22)

For priming the pump is slowly pressed down to its limit and then released. The strong pres-

sure of the spring returns it automatically to its starting position, thereby sucking water into the fil-

ter canister.

(23)

As soon as the canister is full the mains plug can be con-nected to start up the filter.

(24)

Then the closing plug is inserted in the open end of the spray bar.

Note:

Should the water circulation not be complete, due to unfavourable hose conduit, the priming

support can be activated repeatedly.

Controlling the flow rate.

(25)

To adjust the filter performance on the delivery side according to requirement, the lever on the

adapter can be pulled forwards slowly. The float in the inspection glass of the indicator shows the

current flow rate of the water.

Optical Control.

(26)

The indicator provides permanent information on the current amount of circulating water and

thus signals possible faults.

If the float touches the red bar of the scale, this means that full performance is no longer being

achieve and that the filter system must be checked.

16

Summary of Contents for Professionel II 2026

Page 3: ...2026 2028 2126 2128 21 21 22 24 23 25 26 27...

Page 116: ...2026 2028 2126 2128 EHEIM professionel II C 112 gepr fte Sicherheit...

Page 118: ...114 1 2 3 3 4 5 6 7 180 a b c...

Page 119: ...115 8 9 velcro 10 1 5 7676290 C 11 12 13 14 EIM MECH 15 SUBSTRATpro 16 17 17 1 C...

Page 120: ...18 19 2628260 20 21 22 23 Z 24 25 26 116...

Page 121: ...117 4006570 4006570 7345988 27 28 27 C Z Z 29 C 30 31...

Page 122: ...36 37 Z C 32 2616265 1 2 2628260 2616260 Z SUBSTRATpro 33 Z 2628260 34 35 118...

Page 123: ...119 4004570 38 39 40 4009570 41 42 4004550 43 ring 7345988...

Page 124: ...4006570 4006570 EHEIM MECH SUBSTRATpro EHEIM MECH SUBSTRATpro 120...

Page 125: ...4009570 10 EHEIM MECH SUBSTRATpro 7345988 121...

Page 176: ...172 gepr fte Sicherheit C EHEIM professionel II...

Page 177: ...173 173 174 174 175 176 177 180 2026 2028 2126 2128 21 22 23 24 25 26 27...

Page 178: ...174 C C 11 12 13 SUBSTRATpro EHEIMMECH...

Page 179: ...175 25 26...

Page 180: ...176 C SUBSTRATpro...

Page 181: ...177 C 41 42 EHEIM 4004550...

Page 182: ...178 EHEIM MECH SUBSTRATpro SUBSTRATpro EHEIM MECH...

Page 183: ...179 EHEIM MECH SUBSTRATpro...