19

Always lead the mains and extension cables as well as the dedusting

hose from the tool to the back.

Electrical tools have to be inspected visually by a specialist in regular

intervals.

On using the tool, in no case cooling water may seep into the motor or

the electric components.

If water comes out of the drainage hole at the gear neck, stop your

work and have the tool repaired by an authorised service centre.

Perform overhead drilling only with suitable protective appliances

(water catcher).

Always wait until the machine has come to a complete stop before

placing it down.

The tool insert can jam and lead to loss of control

over the power tool.

If the application tool should become blocked, switch the machine

off. Loosen the application tool.

After interruption of your work, restart the tool only after having made

sure that the drill bit is moving freely. When switching on with a blocked

drilling tool, high torque reaction can occur.

The tool may be used only in two-hand operation or with the drill rig.

Keep the handles dry, clean, and free of oil and grease.

Do not touch rotating parts.

Persons under 16 years are not allowed to use the tool.

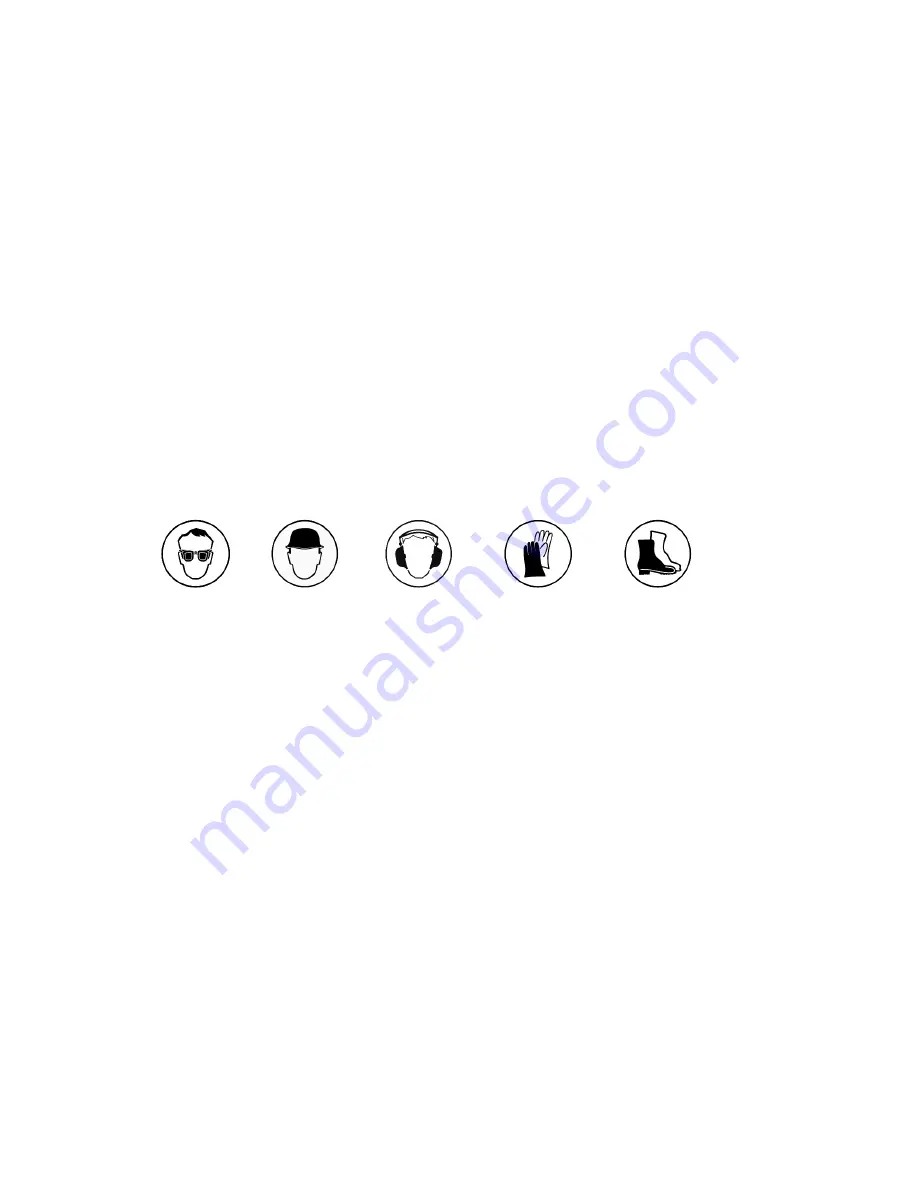

During use, the user and other persons standing nearby have to wear

suitable goggles, helmets, ear protectors, dust mask, protective cloves

and boots.

During manual operation, always hold the tool with both hands

and be fall-safe. Consider the tool’s reaction torque in case of

blocking.

The safety and operating instructions for the drill stand and the

accessories being used are to be strictly observed!

Always work in a carefully considered way and do not use the tool

if you are lacking consideration.

Store the machine in a safe manner when not being used. The

storage location must be dry and lockable. This prevents the

machine from storage damage, and from being operated by

untrained persons.

For further safety instructions, see the enclosure.