23

Drill Bits

Diamond drill bits with a 1 ¼" UNC female thread and R ½" male thread can

be screwed directly onto the working spindle.

Use only appropriate drill bits for the material to be drilled in. You can

protect your tool by using only well balanced drill bits without deformation.

Make sure that the diamond segments have sufficient cutting clearance

towards the bit body.

Changing Drill Bits

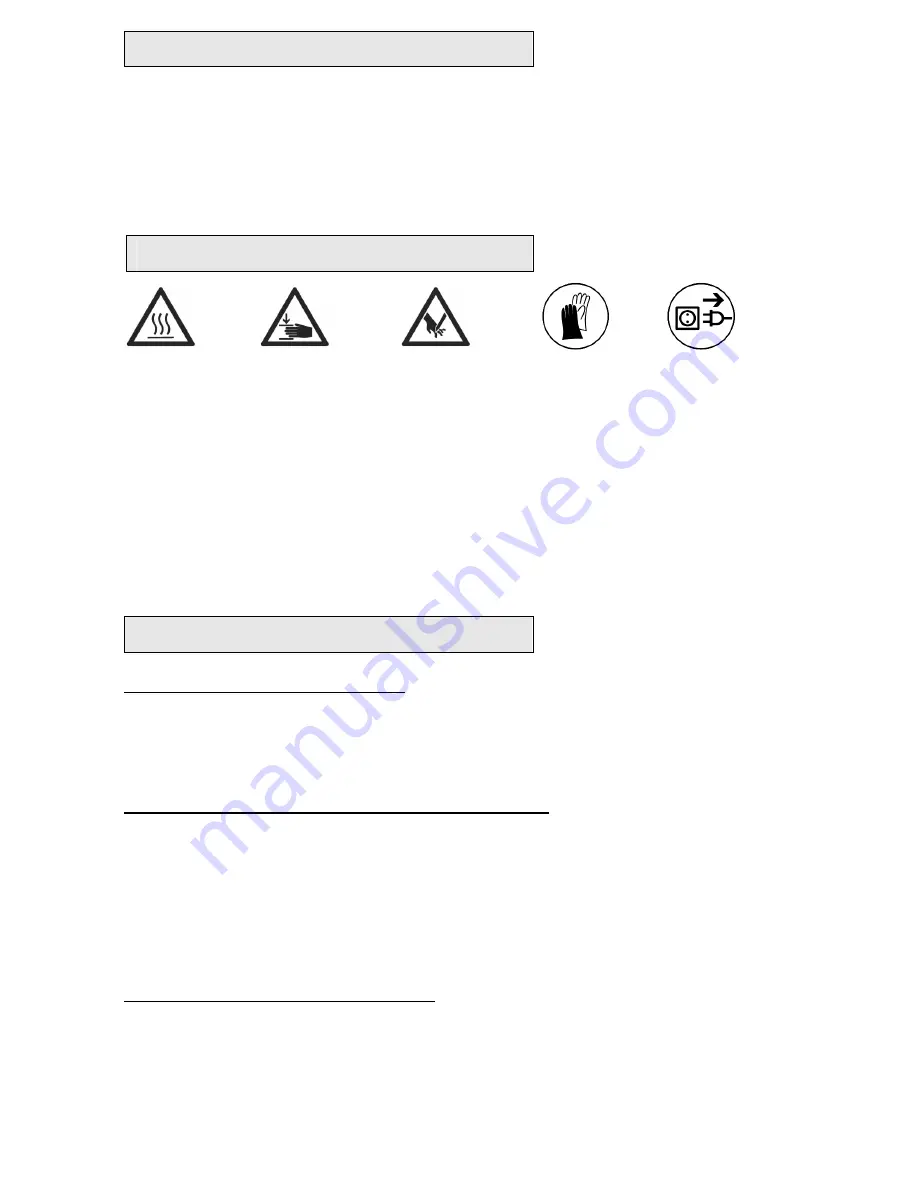

Attention!

When you use or sharpen the machine, it might heat up enormously.

You could burn your hands or get cut or ripped by the segments.

Therefore, always use protective gloves when changing the drill bit.

The drilling spindle has a right-hand thread.

To ease screwing on and off, always use a SW 32 open-end wrench at the

drilling spindle. Never use a hammer, because this may damage both the

drill bit and the tool.

Some water-resistant grease on the drilling spindle threat or a copper ring

between spindle and drill bit will simplify removal of the drill bit.

After Drilling

When you have finished drilling:

Pull the drill bit out of the hole.

Turn the motor off by using the motor switch and not the PRCD

switch.

Close the water supply.

Removal of the core when it sticks in the drill bit:

Separate the drill bit from the motor (if possible).

Put the drill bit in a vertical position.

Knock carefully on the pipe by using a wooden hammer shank till the

drilling core slips out. Never throw the drill bit against a wall by force

or set about it with tools, such as hammer or jaw wrench. Otherwise,

the pipe could go out of shape and neither the drilling core can be

extracted nor the drill bit is reusable.

Removal of the core by blind holes:

Break off the core with a cotter or lever, or in pieces. Lift the core out with

appropriate tongs or drill a hole with a dowel in the core, screw an eyebolt

in and pull the core out.