6

Important! Note!

●

Remove the mains plug before all

maintenance work.

●

In the event that the pump is

often transported in the course of

operation, it should be

cleaned out with clear water after

every use.

●

In case of stationary installation,

the function of the loating switch

should be checked every 3

months.

●

All fibrous particles which may

have built-up inside the pump

housing should be removed with

a water jet.

●

Every 3 months the shaft

ground and as should be

cleaned from mud.

●

Remove deposits on the floater

with clear water.

Cleaning the impeller

If excessive deposits collect in the

pump case you must dismantle

the bottom part of the pump as

follows:

1.

Undo the 4 screws from the

bottom of the intake cage.

2.

Remove the intake cage

from the pump case.

3.

Clean the impeller with clear

water.

Important! Do not put down or

rest the pump onthe impeller!

4.

Assemble in reverse order

Setting the ON/OFF opera-

ting point

The ON and OFF operating point of

the float switch can be set by adju-

sting the float switch in its latching

holder.

Before you put the pump into opera-

tion, please check the following:

●

The float switch must be installed

so that the level of the ON opera-

ting point and the level of the

OFF operating point can be rea-

ched easily and with little force.

To check this, place the pump in

a vessel filled with water, raise

the float switch carefully by hand

and then lower it again. As you

do so, note whether the pump

switches on and off.

●

Make sure that the distance bet-

ween the float switch head and

the latching holder is not too

small. Proper operation is not

guaranteed if the gap is too small.

●

When you set the float switch,

make sure that it does not touch

the base before the pump swit-

ches off. Caution! Risk of dry-run-

ning.

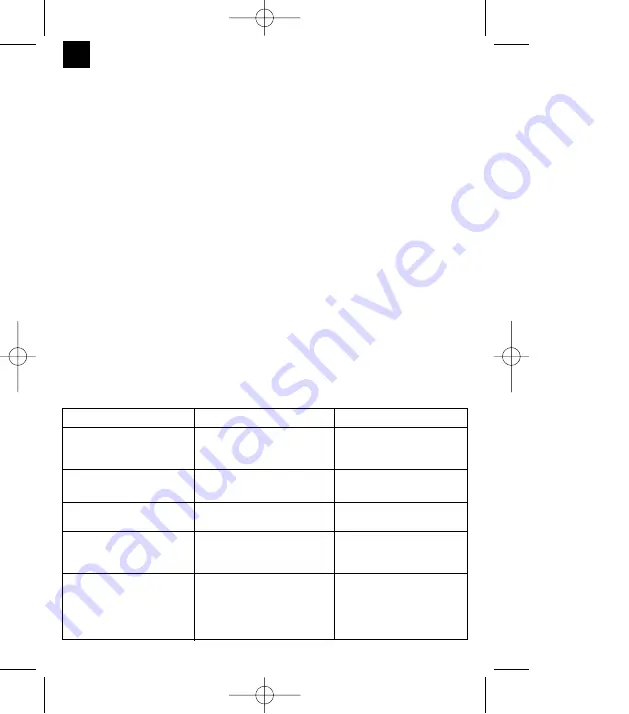

Incidents – Causes – Remedies

Incidents

Pumpe does not start

No flow

Pump does not switch off

Insufficient flow

Pump switches of after short

operating period

Causes

– No mains supply

– Floater does not switch

– Inlet sieve is clogged

– Pressure hose in bent

– Floater cannot sink down

– Inlet sieve is clogged

– Reduced pumping capacity by

dirty and abrasive water

– Thermal cutout stops pumps

due to dirty water

– Water too hot. Thermal-cutout

stops pump

Remedies

– Check mains supply

– Bring floater in a higher

position

– Clean inlet sieve water jet

– Reset hose

– Place pump properly on shaft

ground

– Clean inlet sieve

– Clean pump and replace

worn-out parts

– Remove mains plug. Clean

pump and shaft

– Make sure that a water tem-

perature of max. 35°C is not

exceed

GB

Anleitung ESP 460_1_Niro 30.01.2004 13:22 Uhr Seite 6