handle will engage in the bayonet lock.

Note:

The bayonet lock must be properly latched

whenever you transport the pressure sprayer.

Also, the spray tube should be in the holder pro-

vided for the purpose (Fig. 1/Item 5).

9. Spraying

앬

Release the pump/carry handle from the bayonet

lock by pressing it down and gently turning it

counterclockwise.

앬

Pressure is built up in the tank by pumping the

pump/carry handle (up and down).

Note:

The pumping process can be facilitated by

removing the spray funnel (Fig. 1/Item 10) from

the storage compartment (bootstrap) and holding

the pressure sprayer on the ground with your

foot.

The tank pressure can be read off the pressure

gauge at any time (Fig. 1/Item 9). The maximum

tank pressure (operating pressure) must not

exceed 3 bar. The overpressure valve (Fig.

1/Item 11) triggers at a positive pressure of

3.2 bar and relieves any pressure exceeding this

amount.

Note:

Using a higher pressure increases spray

atomization, however this also increases the

danger of overspray.

Using a lower pressure leads to larger, heavier

droplets, which then more easily drop onto the

ground (causing unnecessary pollution) and

increase the amount of solution required.

Important:

Always carry the pressure sprayer

upright.

앬

Press the trigger lever (Fig. 1/Item 7) on the

spray gun handle to spray.

앬

The spray jet will stop immediately if you let go of

the trigger.

앬

You can direct the spray precisely at even hard-

to-reach areas by bending the swan-neck (Fig.

2/Item 3) at the joints.

앬

Unscrew the nozzle and the swan-neck (Fig.

2/Item 3) from the spray tube to use the spray

funnel (Fig. 1/Item 10). Then screw the spray

funnel onto the spray tube as shown in Figure 4.

Important:

Release all pressure by pulling the

overpressure valve (Fig. 1/Item 11).

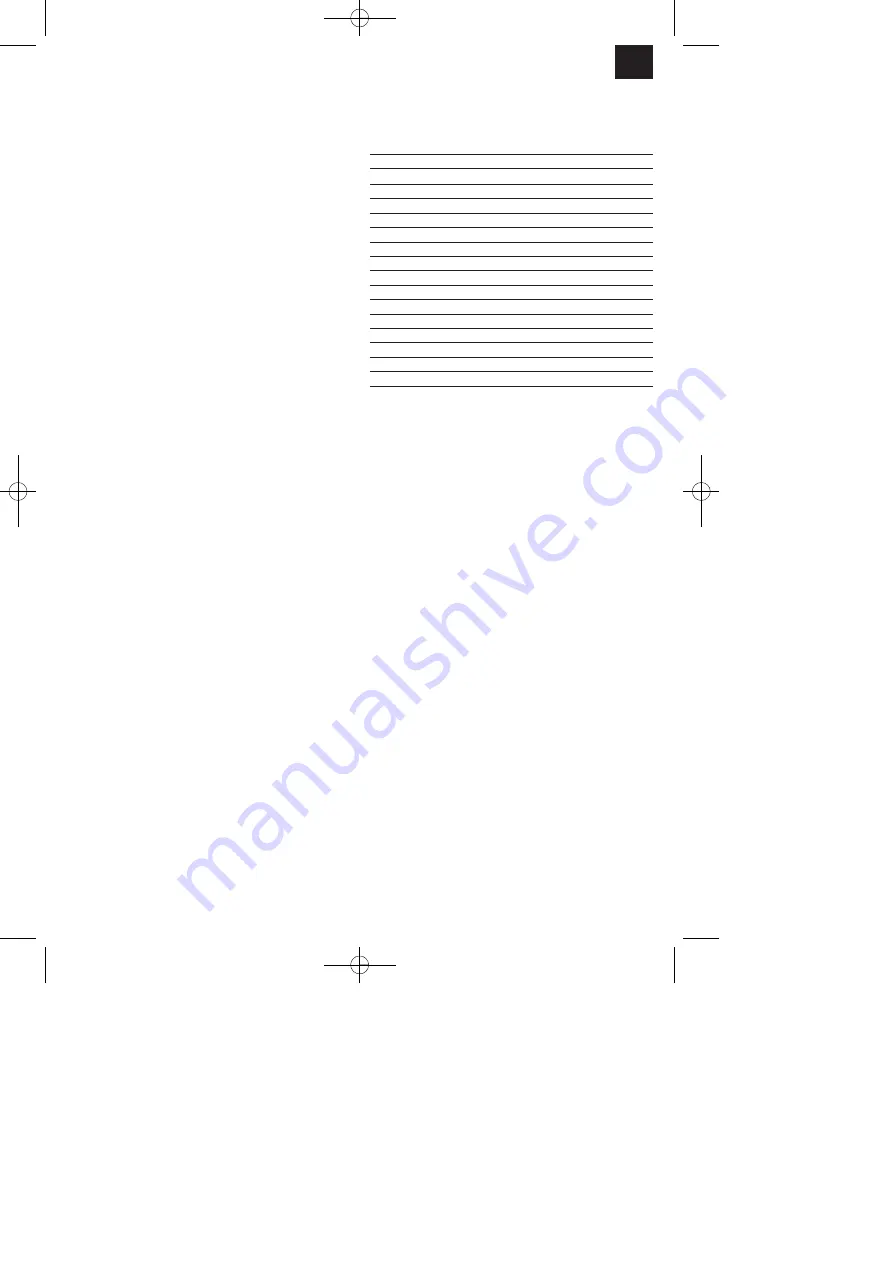

10. Technical data

Maximum fill capacity

5 l

Total volume of tank

7 l

Maximum delivery rate V

max

= 0.45

l/min

Maximum permissible operating pressure

3 bar

Maximum permissible operating temperature + 40 °C

Safety valve/bleed valve

1

Nozzle

hollow taper, 0.7 mm

Nozzle spray angle

max. 60°

Nozzle recoil force

less than 5 N

Net weight

2.8 kg

Residual quantity

0.05 l

Spray pressure

1.5 - 3 bar

Spray quantity

0.3 - 0.45 l/min

Optimal spray pressure

2.0 bar

Optimal spray distance

0.6 m

Spray width at a distance of 0.5 m

0.6 m

Spray quantity at 2 bar

0.35 l/min

Note:

The residual quantity refers to the liquid that

remains in the sprayer when the nozzle starts to leak

air. This liquid cannot be evenly sprayed.

11. Cleaning

After use, clean the unit and leave the sprayer tank

open to dry. Note the cleaning instructions in the

directions for use that came with the chemical in

addition to these cleaning instructions.

Remove any remaining liquid from the tank through

the tankʼs filler opening and store the liquid properly

for subsequent use or dispose of it in accordance

with the applicable regulations.

Perform the following steps to clean the pressure

sprayer:

앬

After the tank has been sprayed empty or after

completely emptying the tank as previously

described, fill the tank with clear water to a level

that amounts to ten times the residual liquid (see

“Technical data”).

앬

Close the tank and forcefully shake the pressure

sprayer several times.

앬

Now spray the contents of the pressure sprayer

on the area you just treated or on an area that

you reserved for this purpose.

앬

Repeat the cleaning process.

앬

The tank can now be drained through the filler

opening.

GB

13

Anleitung NDS 5_SPK7:Anleitung GLDS 5-2 23.03.2007 9:06 Uhr Seite 13