8

GB

Important!

The vibration value changes according to the area of

application of the electric tool and may exceed the

specified value in exceptional circumstances.

Keep the noise emissions and vibrations to a

minimum.

Only use appliances which are in perfect working

order.

Service and clean the appliance regularly.

Adapt your working style to suit the appliance.

Do not overload the appliance.

Have the appliance serviced whenever

necessary.

Switch the appliance off when it is not in use.

Wear protective gloves.

5. Before starting the equipment

Before you connect the equipment to the mains

supply make sure that the data on the rating plate

are identical to the mains data.

Always pull the power plug before making

adjustments to the equipment.

All covers and safety devices have to be properly

fitted before the machine is switched on.

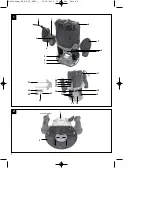

5.1 Extraction port assembly (Fig. 2/Item 1)

Important. For health and safety reasons it is

imperative that you use a dust extractor.

Connect your router to the extraction port (1) of a

vacuum cleaner or a dust extraction device. This

will provide excellent dust extraction on the

workpiece. The benefits are that you will protect

both the equipment and your own health. Your

work area will also be cleaner and safer.

Dust created when working may be dangerous.

Refer to the section entitled “Safety instructions”.

The vacuum cleaner you use for the extraction

work must be suitable for the workpiece material.

Use a special vacuum cleaner if you are handling

harmful materials.

Secure the extraction port (1) to the routing shoe

(2) using the two countersunk screws (f).

The extraction port can be connected to extractor

units (vacuum cleaners) with a suction hose.

The internal diameter of the suction port is 36

mm. Now fit a suction hose of the appropriate

size to the suction port.

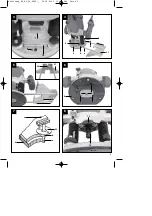

5.2 Safety guard port assembly (Fig. 3/Item 13)

Fit the safety guard (13) as shown in Fig. 3.

5.3 Parallel stop assembly (Fig. 4/Item 21)

Push the guide shafts (a) of the parallel stop (21)

into the holes (b) on the routing shoe (2).

Set the parallel stop (21) to the required

dimension and secure it in place with the wing

screws (3).

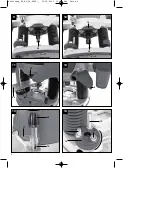

5.4 Compass point assembly (Fig. 5/Item 24)

You can cut circular areas using the compass

point (24).

Secure the compass point (24) to the parallel

stop (21) as shown in the figure. Now fit the

parallel stop (21) with the compass point (24) to

the router. The assembly work is to be carried

out as described in point 5.3, but the parallel stop

(21) must be fitted at an angle of 180° so that the

compass point (24) points downwards (Fig. 5).

Set the required radius between the compass

point (24) and cutter.

Position the compass point (24) in the center of

the circle you wish to route.

5.5 Guide sleeve assembly (Fig. 6-7/Item 25)

Secure the guide sleeve (25) to the routing shoe

(2) using the two countersunk screws (f).

The guide sleeve (25) is guided along the

template (c) using the guide ring (b).

The workpiece (d) must be larger by the

difference of “external edge of guide ring” and

“external edge of router” (e) to obtain a precise

copy.

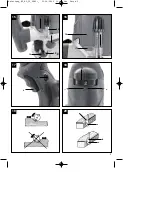

5.6 Fitting / Removing the cutting tool (Fig. 8-11)

Important. Pull out the power plug first.

Important. After working with the router, the

cutting tool will remain very hot for a relatively

long time.

Important. Cutters are very sharp. Wear

protective gloves at all times when handling

cutting tools.

Cutters with a shaft diameter of 6 mm and 8 mm

may be fitted to this router. Most cutters are

available in both sizes.

You can used cutters made of the following

materials:

-

HSS

– Suitable for machining softwood

-

TCT

– Suitable for machining hardwood,

particle board, plastic and aluminum.

Select the appropriate cutting tool for the job in

hand.

When using the cutters for the first time:

Remove the plastic packaging from the cutter

heads.

Clean the nut, clamp and shaft of the cutter

before fitting it.

Anleitung_RT_RO_55_SPK1:_ 23.04.2009 13:25 Uhr Seite 15