GB

14

8. Operating the laser (Fig. 15-19)

8.1 Stationary operation (Fig. 15/16)

To switch on:

Move the ON/OFF switch (46) to the

“I” position.

To switch off:

Move the ON/OFF switch (46) to the

“0” position.

Switch on the laser (45). A laser line is projected

onto the material you wish to process, providing an

exact guide for the cut. You can additionally adjust

the laser with the screw (47). To do so, undo the

screw (47) by a few turns. The laser (45) can now be

moved and adjusted vertically and horizontally on the

adapter (48). Tighten screw (47) again when you are

satisfied with the adjustment.

8.2 Use as a laser level unit (Fig. 15-18)

Remove the screw (47). The laser (45) can now be

taken off the adapter (48) and used as an external

laser level unit. The laser (45) is equipped with two

spirit levels (49) and can therefore be adjusted both

horizontally and vertically. The base plate (50) of the

laser is magnetic, enabling it to be secured on

suitable surfaces.

See Figures 17 and 18 for two examples of use.

8.3 Replacing the battery

Unscrew the 4 screws (51) and remove the base

plate (50). Take out the old batteries and replace

with new ones. Then screw the base plate (50) back

on.

Dismantle the laser before you clean the machine

with water.

9. Cleaning, maintenance, transport

and ordering of spare parts

Always pull out the mains power plug before starting

any cleaning work.

9.1 Cleaning

Keep all safety devices, air vents and the motor

housing free of dirt and dust as far as possible.

Wipe the equipment with a clean cloth or blow it

with compressed air at low pressure.

We recommend that you clean the device

immediately each time you have finished using it.

Clean the equipment regularly with a moist cloth

and some soft soap. Do not use cleaning agents

or solvents; these could attack the plastic parts

of the equipment.

9.2 Maintenance

앬

There are no parts inside the equipment which

require additional maintenance.

앬

Lubricate all moving parts at regular intervals.

앬

Clean off any soiling on the trough (3) and

cooling agent pump (13) at regular intervals,

otherwise the diamond cutting wheel (2) may not

be cooled as required.

9.3 Transport

앬

The coolant must be drained completely before

transport.

앬

Do not lift the machine by any of the safety

devices.

9.4 Ordering replacement parts

Please quote the following data when ordering

replacement parts:

앬

Type of machine

앬

Article number of the machine

앬

Identification number of the machine

앬

Replacement part number of the part required

For our latest prices and information please go to

www.isc-gmbh.info

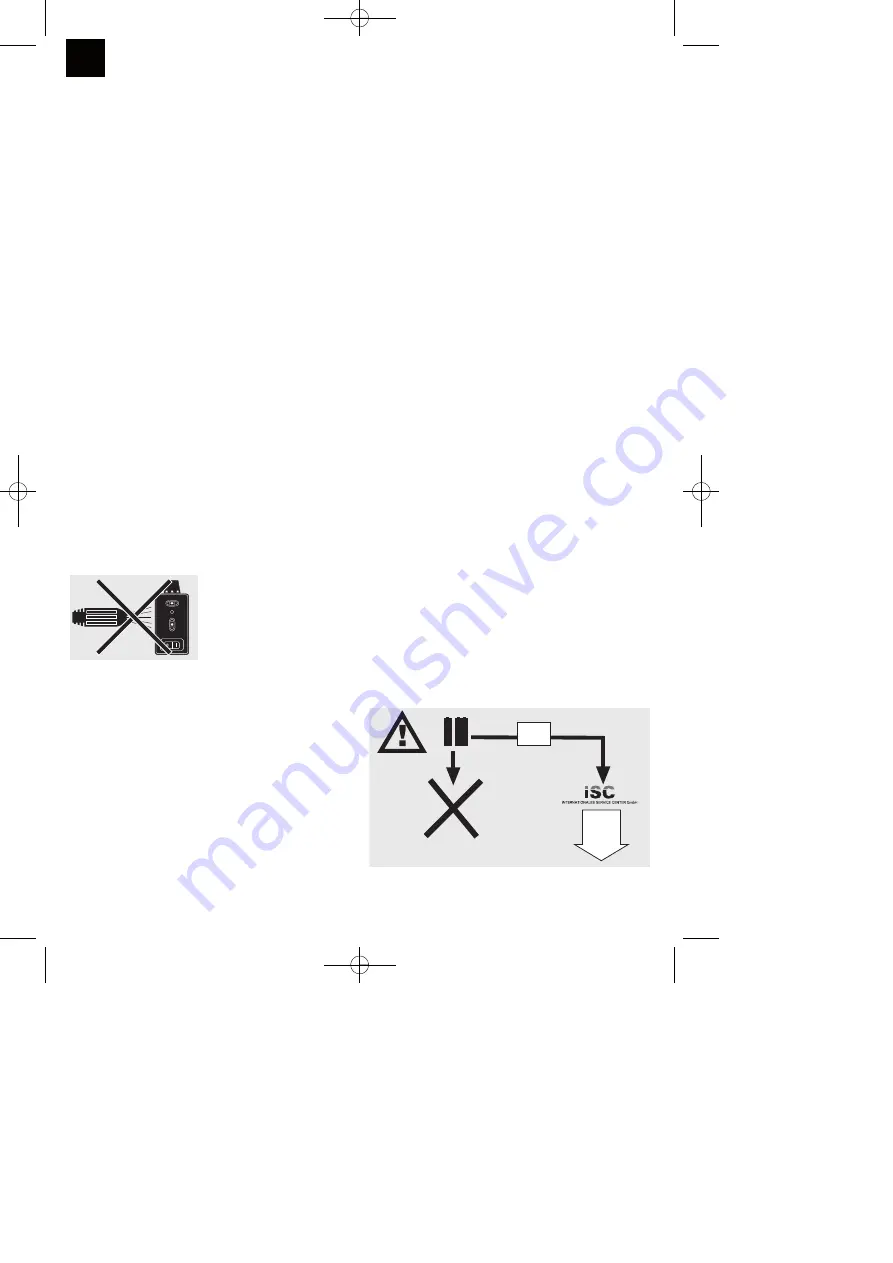

10. Disposal and recycling

The unit is supplied in packaging to prevent its being

damaged in transit. This packaging is raw material

and can therefore be reused or can be returned to

the raw material system.

The unit and its accessories are made of various

types of material, such as metal and plastic.

Defective components must be disposed of as

special waste. Ask your dealer or your local council.

ᪿ

᪾

쾷

Anleitung_RT_TC_520_U_SPK1:_ 17.02.2010 9:35 Uhr Seite 14