GB

- 36 -

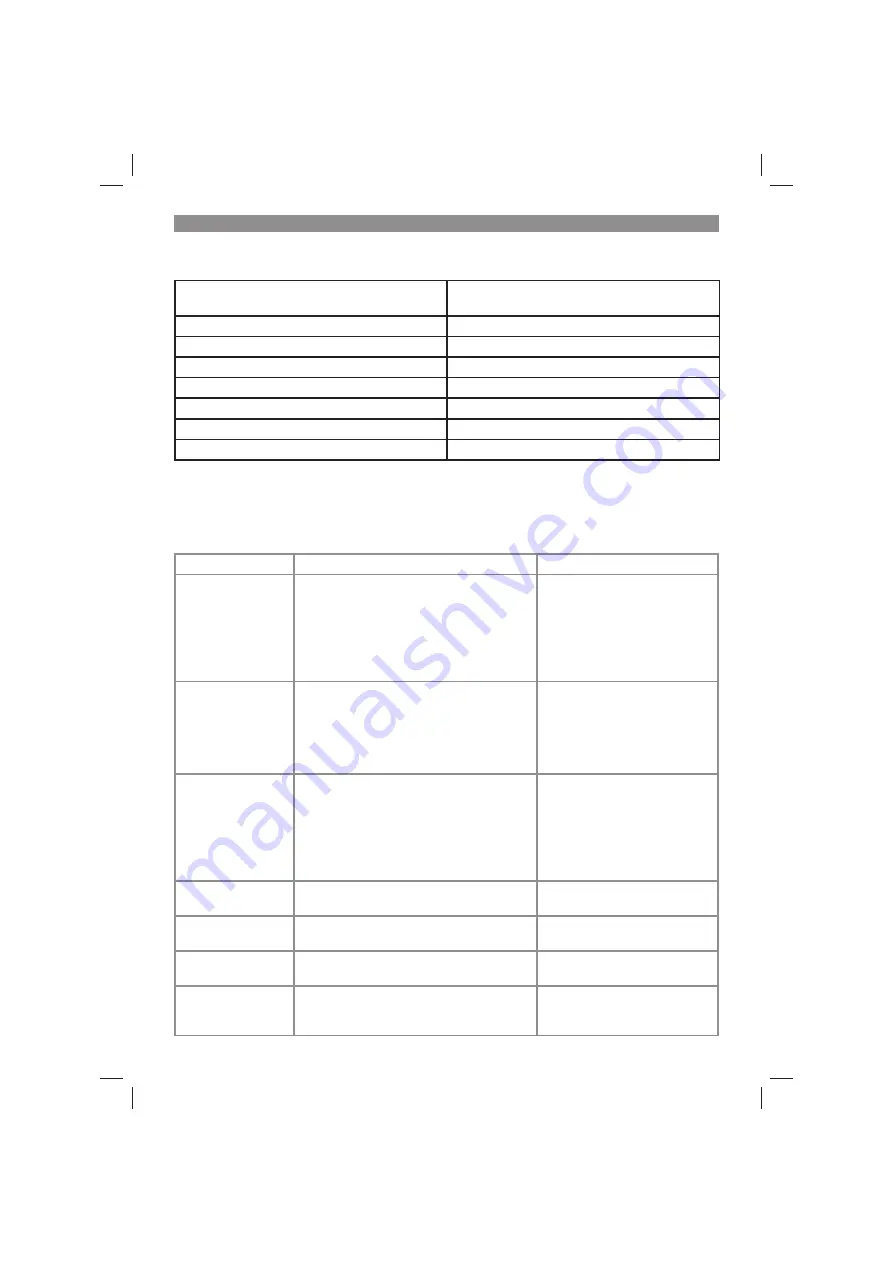

11. Viscosity Table

Examples of spray materials. Follow the

manufacturer‘s instructions!

Draining time in seconds (DIN-sec)

Solvent-borne primers

25-30

Solvent-borne paint

15-30

Water-borne primers

25-30

Water-borne paint

20-25

Wood preservatives, stains, oils

undiluted

Disinfectants

undiluted

Vehicle topcoats

20-25

12. Troubleshooting Guide

Problem

Possible Cause

Solution

No material exits

from the nozzle

Nozzle clogged

Material tube clogged

Max. paint volume control rotated too far

anti-clockwise (-).

Material tube is loose.

No pressure build-up in the container.

Consistency of the material is too thick.

Clean

Clean

Turn clockwise (+)

Insert

Tighten container

Dilute

Material drips from

nozzle after spray-

ing

Nozzle is loose.

Nozzle is worn.

Nozzle seal is worn.

Solids in the air cap or nozzle.

Tighten

Replace

Replace

Clean

Atomization too

coarse

Material viscosity too high

Material volume too high

Max. paint volume control turned too far

clockwise (+).

Dirty nozzle.

Insu

ffi

cient pressure build-up in the con-

tainer

Dilute

Turn the max. paint volume con-

trol anti-clockwise (-)

Clean

Tighten the container

Intermittent („

fl

utte-

ring“) spray

Almost all of the material in the container

has been used up.

Add more

Coating pattern is

too light and uneven

You moved the paint spray gun too fast ac-

ross the surface you are working on.

Move the gun more slowly.

The paint runs or

sags.

You applied too much material.

Turn the max. paint volume con-

trol anti-clockwise (-)

Excessive spray

mist

The gun is held too far away from the object

you are working on.

Hold the gun closer.

Turn the max. paint volume con-

trol anti-clockwise (-)

Anl_SA_TC_SY_700_S_SPK8.indb 36

Anl_SA_TC_SY_700_S_SPK8.indb 36

16.07.2018 09:00:17

16.07.2018 09:00:17