3

INSTALLATION TECHNICAL NOTES

• Installation and maintenance must be

performed only if the power supply has

been turned off.

• Installation and maintenance must only

be performed by qualified personnel in

compliance with current regulations.

• The product must be installed insi-

de an electrical panel protected against

overvoltages.

• The product must be installed in a verti-

cal position with the front / label facing

the front or in a horizontal position with

the front / label facing upwards. Other

product installation positions are not al-

lowed. The bottom position with the front

panel / label facing down is not allowed.

• Keep separated the circuits at 230V (LV)

and the circuits not SELV from circuits

to low voltage (SELV) and from any con-

nection with this product. It is absolutely

forbidden to connect, for any reason

whatsoever, directly or indirectly, the

230V mains voltage to the bus or to other

parts of the circuit.

!

Setup and installation

In order to setup the dip-switch, it is necessary to open

the device front cover, by means of a screwdriver as de-

tailed in the image below.

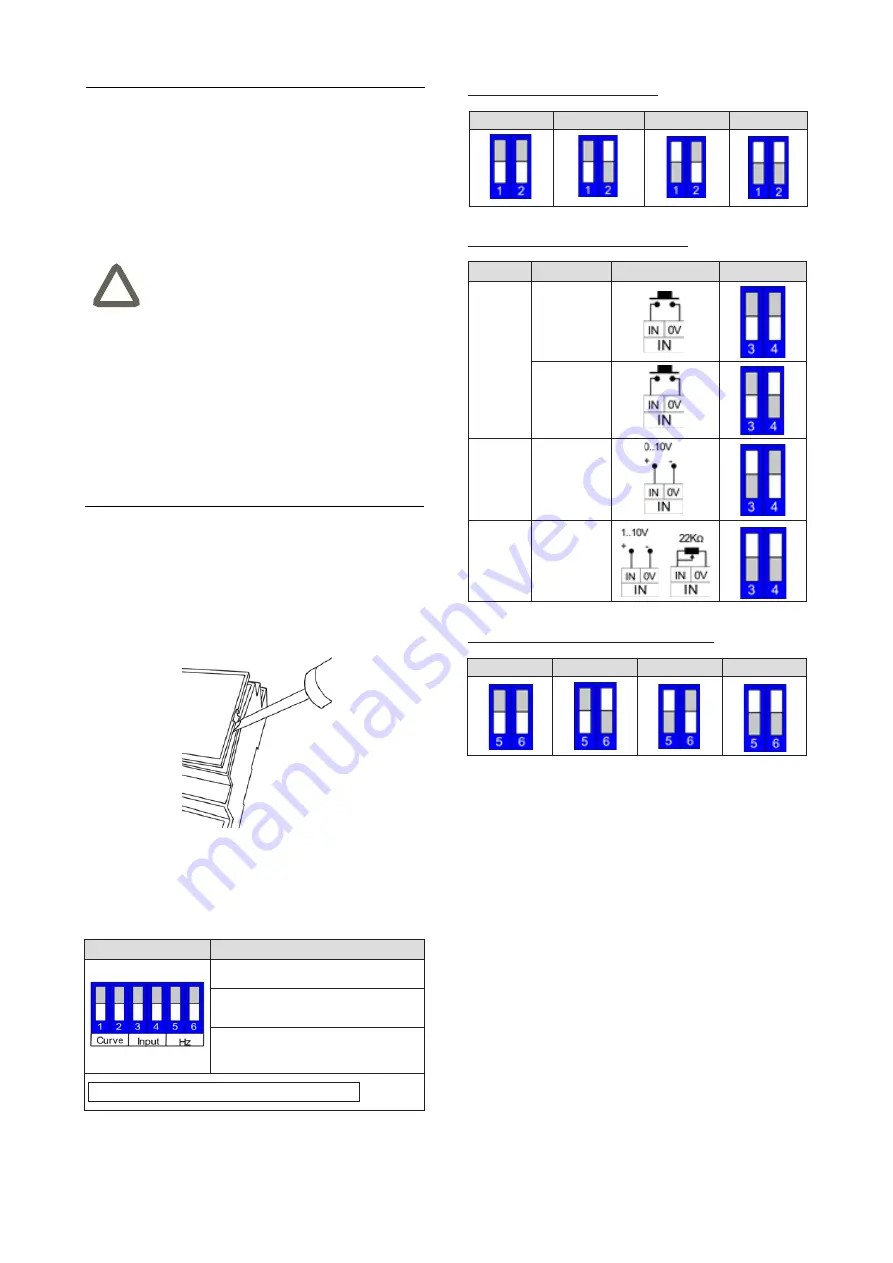

Configuration

Settings

Switch 1-2 = dimming curve

Switch 3-4 = input type

Switch 5-6 = Output Frame Rate –

Frequency

Note: Factory settings = ALL OFF

Switches 1-2 (dimming curve settings)

Default

Exponential

Quadratic

Linear

Switches 3-4 (input local command settings)

Command

Description

Connection

Configuration

Pushbutton

N.O. pushbutton

without memory

N.O. pushbutton

with memory

0 - 10 V

Analog input

0-10V

1 - 10 V

Analog input

1-10V

or

Potentiometer

Switches 5-6 (output dimming frequency settings)

300 Hz

600 Hz

1200 Hz

Reserved

DALI bus line and command connections

The connection to the DALI bus network and the local

commands is done via the screw terminal, located on the

front of the device in the upper part.

The length of the connection cables between the local

commands (N.O. Pushbutton, 0-10V, 1-10V, Potentiome-

ter or other) and the product must be less than 10m; the

cables must be dimensioned correctly and they should be

isolated from every wiring or parts at voltage not SELV.

Use double insulated shielded and twisted cables.

The length and type of the connection cables to the DALI

bus must be compliant with the protocol specification and

with the present regulations and they should be isolated

from every wiring or parts at voltage not SELV. Use dou-

ble insulated shielded and twisted cables.

All the devices and the control signal connected to the

DALI bus and to the local command (N.O. Pushbutton,

0-10V, 1-10V, Potentiometer or other) must be SELV (the

devices connected must be SELV or supply a SELV si-

gnal).

The 6-way dip-switch setting (under the front cover) offers

a wide choice of possible configurations.