- 4 -

3. Maintenance

3.1 Hydraulic oil

Please check the oil level every six months. The oil can be hydraulic oil:

ISO VG32, its viscosity should be 32cSt at 40

o

C, total volume is about

4.0 liters.

3.2 Daily check and maintenance

It is necessary to check the stacker daily. Special attention should be

to the wheels and axles of debris stuck in between which may block the

wheels. Check the forks and the mast, the chain, the battery should be

checked as well. The forks should be unloaded and lowered in the lowest

position when not in use.

3.3 Lubrication

Use motor oil or grease to lubricate all movable parts every 3 months.

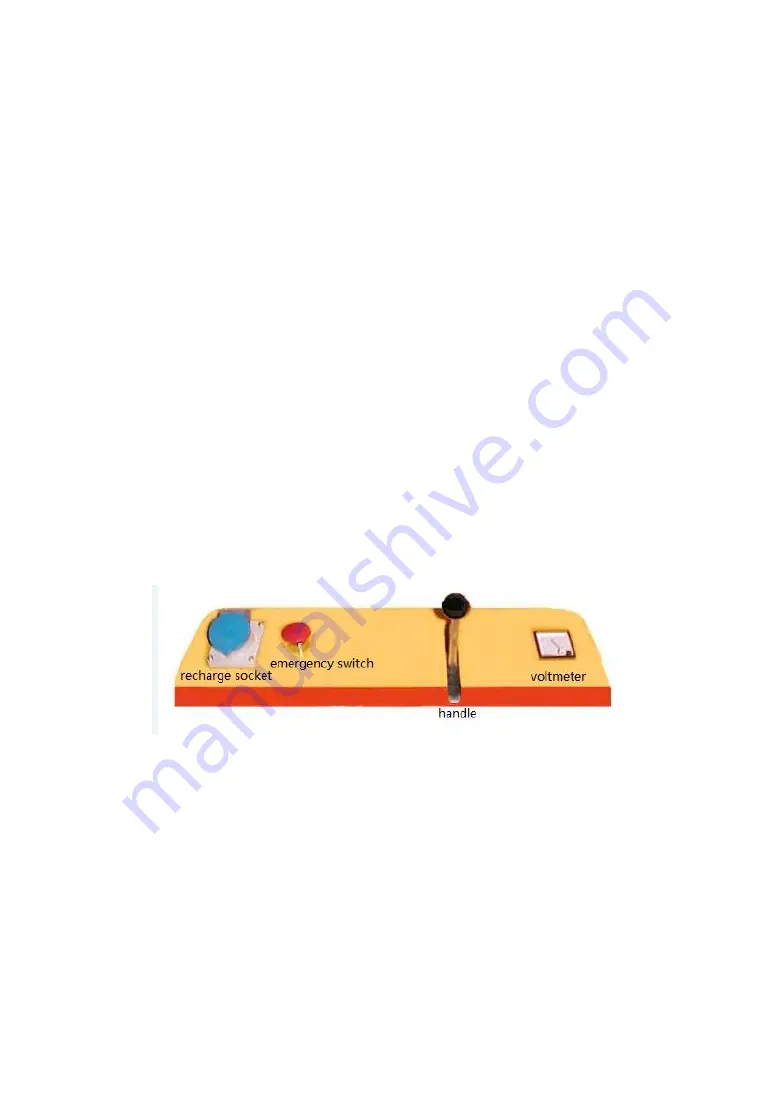

4. Control panel

Pic.1

4.1 Emergency switch

Whenever you press this switch downwards, it will immediately switch

the power off, and when you pull the it back up it will switch the power

back on.

4.2 Voltage meter

It indicates the voltage of battery. When its voltage is less than 10 Volt,

you should recharge it.

4.3 Control handle

This control handle lowers and raises the forks.

4.4 Recharging socket

Summary of Contents for EA15A

Page 9: ... 8 ...