- 12 -

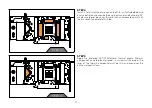

CHECKING THE CONTACT IN CASE OF HIGH TEMPERATURES

If necessary, temporarily remove the water block to check for uniform

surface contact between the block and components. Pay special

attention to the VRM section of the graphics card. Check whether

the water block makes contact with the intended integrated circuit.

Then repeat Steps from the previous section to re-attach the block.

In case you fail to obtain good contact, please check

again or contact our support service at

https://www.ekwb.com/customer-support/.

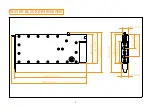

STEP 6

ATTACHING THE BACKPLATE

Use ten (10) M2.5 x 8 AX1 screws. Tighten the screws evenly using

the Phillips head screwdriver.

The screws must be present on the places marked below:

STEP 6

M2.5 x 8 AX1 SCREW