5

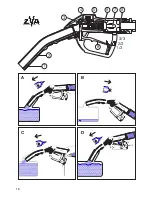

HINTS FOR PROPER HANDLING

INSERT THE SPOUT FULLY INTO THE TANK

. The ball of the safety valve rolls forward

to open the safety cut out. This is the best way to fuel.

Make sure that the ZVA is hooked firmly into the fill pipe so that it cannot slip out

during refuelling

.

With some near horizontal fill pipes version

A

is not possible. The safety cut-out attitude

valve prevents the valve from opening. The ball rolls backwards blocking the sensing path

and the nozzle trips off continuously.

With situation

B

lift and hold the nozzle so that the ball now rolls forward opening up the

sense path. Refuelling is now possible provided the nozzle is kept in this position.

DO NOT FILL TOO FAST

: Splashing fuel can trip the nozzle before the tank is full. Some

filler necks are difficult to refuel. Fuel at lower speeds to avoid fuel blow backs. The

flowrate can be adapted to the capacity of the filler neck by the three - speed lever latch.

First position

3/3 =

Fully opened for straight and near vertical fill pipes

Middle setting 2/3 =

Reduced output for narrower fill pipes.

Lower position 1/3 =

Slow position for poorly vented pipes.

THE AUTOMATIC SHUT OFF WILL ALSO WORK IF THE LEVER IS HELD OPEN MANUALLY,

according to EN 13012. Once the fuel touches the sensing port (1) the automatic cuts off. Topping

up is possible.

A FEW DROPS OF FUEL WILL REMAIN IN THE NOZZLE SENSING PORT

( 1 ). Always tilt the

nozzle forward into the tank to drain for a few moments before returning it to the nozzle boot.

Then the next user will not be surprised by drips.

PLEASE NOTE

The ZVA 25 is approved for all gasoline and diesel fuels in a pressure range of 0,5 – 3,5 bar

( special type with stronger main valve spring: up to 5 bar ) and flowrate up to 140 litre /minute .

The ZVA opens automatically when the pressure exceeds 6 bar ( special type: 8,5 bar ). If it is

intended to use it for other applications you should consult your supplier who will be pleased to

advise its suitability on receipt of full details, including fluid, and operating conditions.

GUARANTEE

We guarantee against defective materials and manufacturing up to 18 months from date

of supply. If the supply date cannot be established, the date code on the nozzle applies

( e.g.

•

18 = 1

st

quarter 2018 ).

Excluded are nozzles and parts subjected to wear and tear, abuse and to contamination.

Furthermore excluded are damages by misuse, indirect damages and costs, travelling

related to exchange and repair work. We refuse any liability for consequential loss or

damage resulting from the use of our nozzle.

A

B

C

D

Description see page 16