29

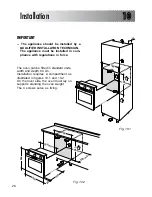

GENERAL

– The connection to the electrical network

must be carried out by qualified person-

nel and must be according to existing

norms.

– The appliance must be connected to the

electrical network verifying above all that

the voltage corresponds to the value

indicated on the specifications plate and

that the cables section of the electrical

plant can bear the load which is also

indicated on the plate.

– If the appliance is supplied without a

power supply plug and if you are not

connecting directly to the mains, a stan-

dardized plug suitable for the load must

be fitted.

– The colours of the wires in the appli-

ance power cable may not correspond

with the colours marked on the termi-

nals of your electrical plug. The plug

should always be wired as follows:

●

connect the green/yellow wire to the

terminal marked with the letter E or

the earth symbol or coloured

green/yellow;

●

connect the blue wire to the terminal

marked with the letter N or coloured

black;

●

connect the brown wire to the ter-

minal marked with the letter L or

coloured red.

The connection of the appliance to

the grounding unit is mandatory.

The manufacturer declines every

responsability for any inconve-

nience resulting from the inobser-

vance of this condition.

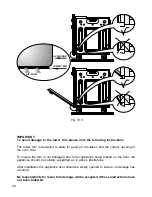

Electrical section

1111

Before effecting any intervention

on the electrical parts the appli-

ance must be disconnected from

the network.

– The bi-polar plug must be connected to

an outlet connected to the grounding

unit in conformity to security norms.

– If the oven is to be connected directly to

the mains, it must be placed with an

omnipolar switch with minimum opening

between the contacts of 3 mm between

the appliance and the mains.

– The power supply cable must not touch

the hot parts and must be positioned so

that it does not exceed 75°C at any

point.

– Once the oven has been installed, the

switch or socket must always be acces-

sible.

– If the power supply cable is damaged it

must be substituted by a suitable cable

available in the after sales service.

N.B. For connection to the mains, do

not use adapters, reducers or branch-

ing devices as they can cause over-

heating and burning.

If the installation requires alterations to

the domestic electrical system call an

expert.

He should also check that the socket

cable section is suitable for the power

absorbed by the appliance.

Summary of Contents for EBO 1726 BK

Page 25: ...25 Advice for the installer ...

Page 31: ...31 ...