17

GAS TAPS

Periodic lubrication of the gas taps must be

carried out by specialist personnel only.

In the event of operating faults in the gas

taps, call the Service Department.

INSIDE OF OVEN

The oven should always be cleaned after

use when it has cooled down.

The cavity should be cleaned using a mild

detergent solution and warm water.

Suitable proprietary chemical cleaners

may be used after first consulting with the

manufacturers recommendations and te-

sting a small sample of the oven cavity.

Abrasive cleaning agents or scouring pads/

cloths should not be used on the cavity sur-

face.

NOTE:

The manufacturers of this applian-

ce will accept no responsibility for damage

caused by chemical or abrasive cleaning.

Let the oven cool down and pay special

attention no to touch the hot heating

elements inside the oven cavity.

Fire risk! Do not store flammable material

in the oven.

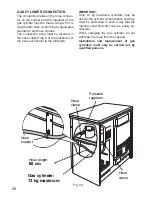

OVEN DOOR

The internal glass of the oven door can be

easily removed for cleaning by unscrewing

the two lateral fixing screws (fig. 6.1).

BURNERS

They can be removed and washed with

soapy water only.

They will remain always perfect if cleaned

with products used for silverware.

After cleaning or wash, check that burner-

caps and burner-heads are dry before pla-

cing them in the respective housings.

Check that the electrode

S

(figs. 6.2, 6.4)

next to each burner is always clean to en-

sure trouble-free sparking.

Note: The electrode “S” must be very

carefully cleaned.

To avoid damage to the electric ignition

do not use it when the burners are not

in place.

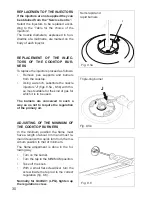

CORRECT REPLACEMENT OF THE

SEMI-RAPID AND RAPID BURNERS

It is very important to check that the burner

flame distributor “

F

” and the cap “

C

” has

been correctly positioned (see figs. 6.2-

6.3) - failure to do so can cause serious

problems.

CORRECT REPLACEMENT OF THE

TRIPLE RING BURNER

The triple ring burner must be correctly po-

sitioned (see fig. 6.6); the burner rib must

be enter in their logement as shown by the

arrow (see fig. 6.4).

The burner correctly positioned must not

rotate (fig. 6.5).

Then position the cap

A

and the ring

B

(figs. 6.5 - 6.6).

Fig. 6.1

Summary of Contents for EEC 863

Page 18: ...18 A B S Fig 6 4 Fig 6 5 Fig 6 6 S F C Fig 6 3 Fig 6 2 ...

Page 33: ...33 ...

Page 34: ...34 ...

Page 35: ...35 ...