0301 / 13 010 881C

30

Service

Maintenance

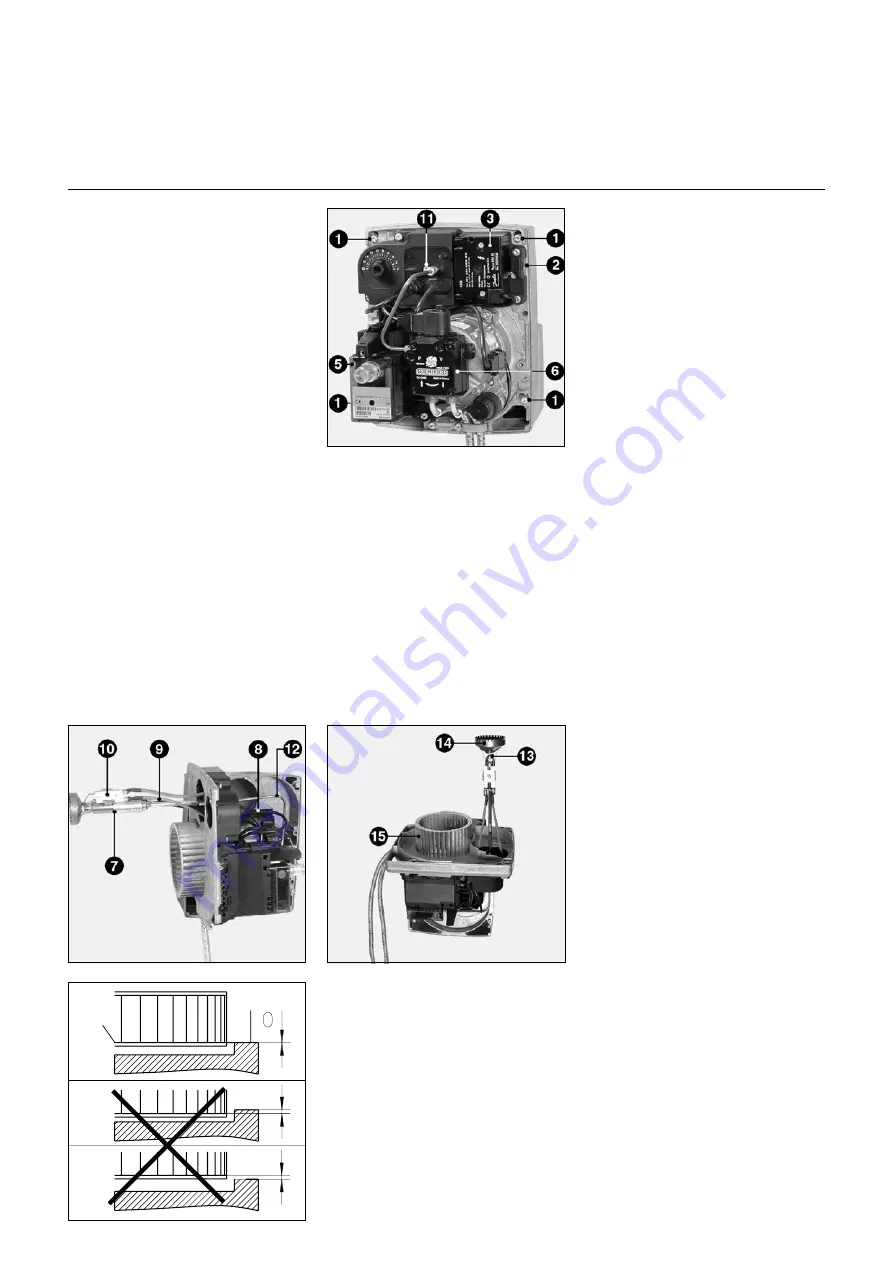

1

Fixing screws

2

Hanger opening

3

Ignition transformer

5

Control and safety unit

6

Oil burner pump

7

Nozzle line

8

Flame monitor

9

Nozzle line el. connection

10

Electrode block

11

Burner head adjusting screw

12

Oil supply connection, Nozzle line

13

Nozzle

14

Turbulator

15

Fan wheel

Fan wheel assembly

Refer to the positions shown in the

diagram on the left when replacing the

motor and fan wheel. The inner flange

A

of the fan wheel must be positioned

level with the device base plate

B

.

Insert a steel rule between the fan

wheel blades and use it to lever points

A

and

B

into alignment. Tighten the

threaded pin on the fan wheel

(maintenance position 2).

A

B

All boiler and burner servicing work

should be carried out by an

appropriately trained heating service

specialist. In order to ensure that the

unit is serviced according to the

maintenance schedule, users are

recommended to enter into a

maintenance contract.

Important

Always shut off the power supply

before carrying out maintenance work

or cleaning tasks.

Checking the exhaust gas

temperature

·

Carry out regular checks to

determine exhaust gas temperature.

·

The boiler must be cleaned whenever

the exhaust gas temperature

exceeds the startup setting by more

than 30K.

·

Fit an exhaust gas temperature

indicator to simplify this checking

procedure.

Maintenance positions

With the screws

1

loosened, the device

base plate can be moved into either of

two maintenance positions.

Position 1

Designed mainly to be used when

replacing the nozzle line.

·

Unscrew oil supply connection

12

·

Unplug unit

9

·

Remove electrode block

10

·

Turn adjusting screw

11

anticlockwise

Position 2

Designed specifically for nozzle and fan

wheel replacement. This position allows

the nozzle to be replaced without

having to drain the nozzle rod.

Burner servicing positions

Position 1

For working, for example, on the pump

Position 2

For working, for example, on the burner

head

Burner maintenance operations

Servicing position 1

·

All oil-bearing components (hoses,

pump, nozzle feed tube) and their

respective couplings should be

checked for tightness and signs of

wear, and replaced as required.

·

Check all electrical connections and

leads for signs of damage, and

replace as required.

·

Check pump filters and clean as

required.

Servicing position 2

·

Clean fan wheel and housing, and

inspect for signs of damage.

·

Inspect and clean the burner head.

·

Dismantle the baffle plate.

·

Replace the oil nozzle.

·

Check ignition electrodes and

readjust or replace as required.

·

Fit burner head. Maintain settings

(see page 28).

·

Fit burner.

·

Start burner, check exhaust-gas data,

correct burner settings as required.

·

Check flame-monitoring device for

correct functioning (see page 29).

Summary of Contents for EK01B.4 L

Page 32: ...0301 13 010 881C 32...

Page 34: ...0301 13 010 881C 34...

Page 42: ...0301 13 010 881C 42 Notizen...

Page 43: ...43 0301 13 010 881C Notizen...