09/2005 - Art. Nr. 13 019 533A

7

Installation

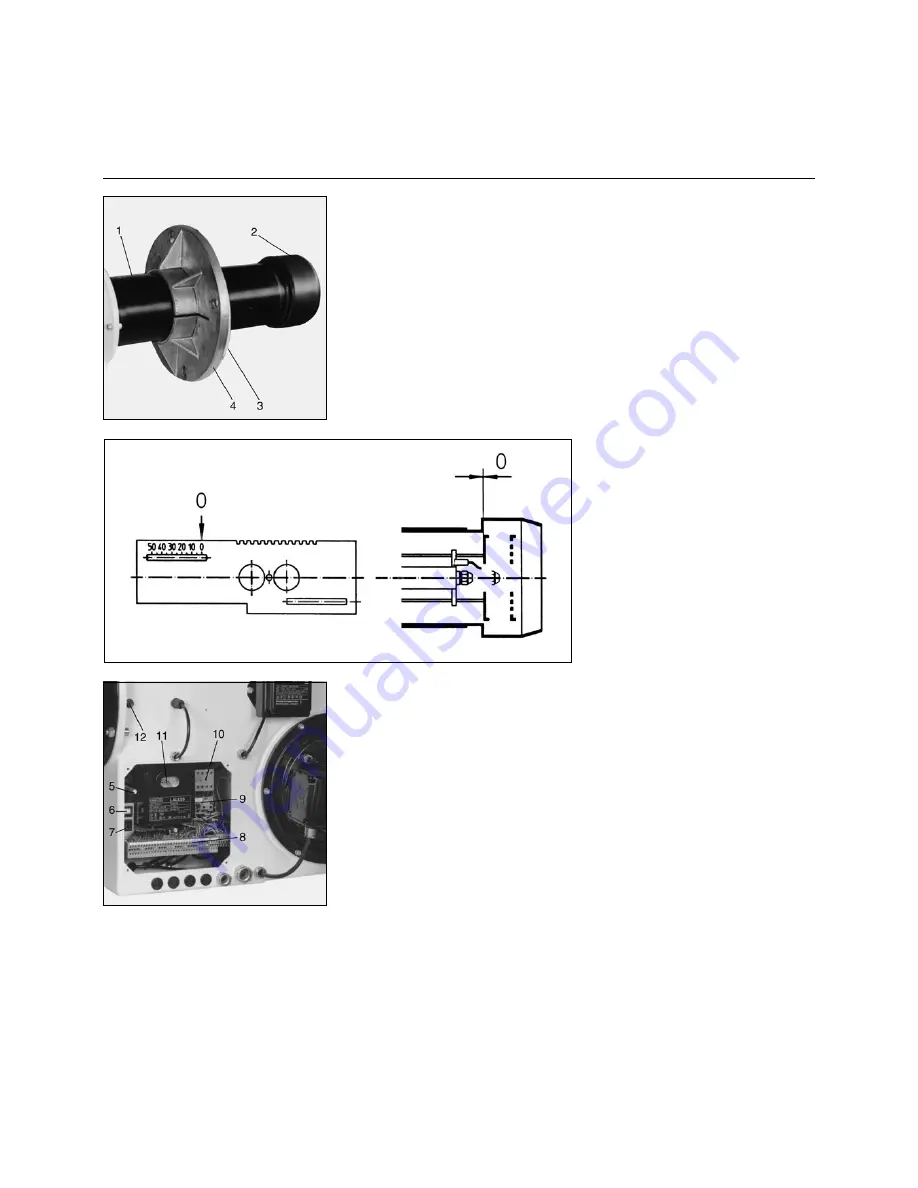

Mounting the burner to the heat generator

Zero point adjustment

Electrical connection

Mounting the burner to the heat

generator

To mount the burner connecting flange

to the heat generator, prepare the con-

necting plate according to the dimen-

sions given on page 4. The connecting

flange

4

with the insulating base

3

have

been factory-mounted to the front of the

burner tube.

·

Set the desired burner tube length in

the furnace by moving the flange on

the burner tube

·

Insert the burner into the opening of

the heat generator and secure it.

Inspection glass cooling

To keep the boiler inspection glass cool

and clean, a cooling line may be

connected to connection

12

R

1/4

”.

The cooling line can be either a hose or

a copper pipe.

A hose union is enclosed with the

burner.

To connect a copper pipe, a suitable

clamping ring connection is required.

Zero point adjustment, flame cup

Before the burner is operated for the

first time, the zero point must be

checked and adjusted, if necessary, so

that the zero mark on the scale corre-

sponds to the zero position in the

burner head. Adjustment is made by

displacing the flame cup after releasing

the screw

1

.

Electrical connection

Electric wiring must be carried out by

an

authorized electrician

according to

the enclosed wiring diagram.

The connecting terminals are located in

the built-in switch box.

For cable connection, ensure the

following:

·

Connect to terminal strip

8

.

·

Provide sufficient length of cable so

that the burner and the boiler door

can be opened.

·

Do

not

install the sensor lead in the

multi-conductor cable.

The electric module can be removed for

connection, replacement or adjustment

of components.

5

Lock nut for electric module

6

Pushbutton, stage 1 - stage 2

7

Pushbutton On/Off

8

El. connecting terminals

9

Overload relay

10 Protective motor switch

11 Automatic burner control unit with

reset button

12 Connection for inspection glass

cooling

Disassembling the electric module

·

Set the main switch to off, remove

the fuse

·

Release the lock nuts

5

·

Carefully remove the electric module.

Caution!

Never apply voltage to the electric

module after disassembly.

After making the connections, check all

system components for correct wiring.

Then start the motor for a short time to

check its sense of rotation.