ELCO S.r.l. - ELK 38 - OPERATING INSTRUCTIONS - Vr. 02 - ISTR 06261 - PAG. 1

MICROPROCESSOR-BASED

DIGITAL

ELECTRONIC CONTROLLER

OPERATING INSTRUCTIONS

Vr. 02 (ENG) - cod.: ISTR 06261

EL.CO. S.r.l.

VIA MARCONI, 49

36030 PIEVEBELVICINO (VI) ITALY

TEL.: +39 0445 661722

FAX: +39 0445 661792

internet : http:\\www.elco-italy.com

e-mail: info@elco-italy.com

FOREWORD:

This manual contains the information necessary for the product to

be installed correctly and also instructions for its maintenance and

use; we therefore recommend that the utmost attention is paid to the

following instructions.

Though this manual has been issued with the greatest care, ELCO

S.r.l. will not take any responsibility deriving from its use.

The same applies to each person or Company involved in the

issuing of this manual.

This document is the exclusive property of ELCO S.r.l. which

forbids any reproduction and divulgation , even in part, of the

document, unless expressly authorized.

ELCO S.r.l. reserves the right to make any formal or functional

changes at any moment and without any notice.

INDEX

1

INSTRUMENT DESCRIPTION

1.1

GENERAL DESCRIPTION

1.2

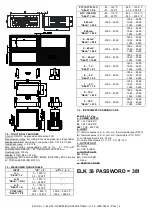

FRONT PANEL DESCRIPTION

2

PROGRAMMING

2.1

FAST PROGRAMMING OF SET POINT

2.2

SELECTION OF CONTROL STATE AND PARAMETER

PROGRAMMING

2.3

PARAMETER PROGRAMMING LEVELS

2.4

CONTROL STATES

2.5

ACTIVE SET POINT SELECTION

3

INFORMATION ON INSTALLATION AND USE

3.1

PERMITTED USE

3.2

MECHANICAL MOUNTING

3.3

ELECTRICAL CONNECTIONS

3.4

ELECTRICAL WIRING DIAGRAM

4

FUNCTIONS

4.1

MEASURING AND VISUALIZATION

4.2

OUTPUTS CONFIGURATION

4.3

ON/OFF CONTROL

4.4

NEUTRAL ZONE ON/OFF CONTROL

4.5

SINGLE ACTION PID CONTROL

4.6

DOUBLE ACTION PID CONTROL

4.7

AUTO-TUNING AND SELF-TUNING FUNCTIONS

4.8

REACHING OF SET POINT AT CONTROLLED SPEED

AND AUTOMATIC COMMUTATION BETWEEN TWO

SET POINTS

4.9

SOFT-START FUNCTION

4.10 ALARM FUNCTIONS

4.10.1 ALARM OUTPUT CONFIGURATION

4.10.2 ALARM HYSTERESIS

4.11 LOOP BREAK ALARM FUNCTION

4.12 FUNCTION OF KEY “U”

4.13 PARAMETERS CONFIGURATION BY KEY01

5

PROGRAMMABLE PARAMETERS

5.1

PARAMETERS TABLE

5.2

PARAMETERS DESCRIPTION

6

PROBLEMS , MAINTENANCE AND GUARANTEE

6.1

ERROR SIGNALLING

6.2

CLEANING

6.3

GUARANTEE AND REPAIRS

7

TECHNICAL DATA

7.1

ELECTRICAL DATA

7.2

MECHANICAL DATA

7.3

MECHANICAL DIMENSIONS, PANEL CUT-OUT AND

MOUNTING

7.4

FUNCTIONAL DATA

7.5

MEASUREMENT RANGE TABLE

7.6

INSTRUMENT ORDERING CODE

1 - INSTRUMENT DESCRIPTION

1.1 - GENERAL DESCRIPTION

ELK 38 is a “single loop” digital microprocessor-based controller,

with ON/OFF, Neutral Zone ON/OFF, PID single action, PID dual

action (direct and reverse) control and with AUTO-TUNING FAST

function, SELF-TUNING function and automatic calculation of the

FUZZY OVERSHOOT CONTROL parameter for PID control.

The PID control has a particular algorithm with TWO DEGREES OF

FREEDOM that optimises the instrument’s features independently in

the event of process disturbance and Set Point variations.

The process value is visualized on 4 red displays, while the output

status is indicated by 2 LED displays.

The instrument is equipped with a 3 LED programmable shift

indexes .

The instrument provides for the storage of 4 Set Points and can

have up to 2 outputs: relay type or can drive solid state relays type

(SSR).

Depending on the model required the input accept:

C: Thermocouples temperature probes (J,K,S and ELCO IRS

Infrared sensors), mV signals (0..50/60 mV, 12..60 mV),

Thermoresistances PT100.

ELK 38