ELCO S.r.l. - ELK 38 - OPERATING INSTRUCTIONS - Vr. 02 - ISTR 06261 - PAG. 3

Release the key and by using the “UP” and “DOWN” keys, it will be

possible to select a new group (if present).

To exit the programming mode, no key should be pressed for

approx. 20 seconds, or keep the “UP” or “DOWN” pressed until exit

from the programming mode is obtained.

To enter the menu "ConF" a PASSWORD is required.

At this request, enter, using keys “UP” and “DOWN”, the number

reported on the last page of this manual and push key “P”.

If an incorrect password is entered, the instrument returns to the

previous control state.

If the password is correct, the display will visualise the code

identifying the first group of parameters (“

]

SP “) and with keys “UP”

and “DOWN” it will be possible to select the desired group of

parameters

The programming and exit modes for the “ConF” menu are the

same as those described for menu “OPEr”.

2.3 - PARAMETERS PROGRAMMING LEVELS

The menu “OPEr” normally contains the parameters used to

program the Set Point; however it is possible to make all desired

parameters appear or disappear on this level, by following this

procedure:

Enter the menu “ConF” and select the parameter to be made

programmable or not programmable in the menu “OPEr”.

Once the parameter has been selected, if the LED SET is switched

off, this means that the parameter is programmable only in the

menu “ConF”, if instead the LED is on, this means that the

parameter is also programmable in the menu “OPEr”.

To modify the visibility of the parameter, push key “U” : the LED SET

will change its state indicating the parameter accessibility level (on =

menu ”OPEr” and “ConF”; off = menu “ConF” only).

The active Set Point and the alarm thresholds will only be visible on

the Set Point fast programming level (described in par. 2.1) if the

relative parameters are programmed to be visible (i.e. if they are

present in the menu “OPEr”).

The possible modification of these Sets, with the procedure

described in par. 2.1, is instead subordinate to what is programmed

in par. “Edit” (contained in the group “

]

PAn “).

This parameter can be programmed as :

=SE : The active Set Point can be modified while the alarm

thresholds cannot be modified.

=AE : The active Set Point cannot be modified while the alarm

thresholds can be modified

=SAE : Both the active Set Point and the alarm thresholds can be

modified

=SAnE : Both the active Set Point and the alarm thresholds cannot

be modified

2.4 - CONTROL STATES

The controller can act in 3 different ways : automatic control (rEG),

control off (OFF) and manual control (OPLO).

The instrument is able to pass from one state to the other :

- by selecting the desired state from the main selection menu suing

the keyboard.

- By using the key “U” on the keyboard; suitably programming par.

“USrb” (“USrb” = tunE; “USrb” = OPLO; “USrb” = OFF) it is possible

to pass from “rEG” state to the state programmed on the parameter

and vice versa.

- Automatically (the instrument swaps into "rEG" state at the and of

the auto-tuning execution)

When switched on, the instrument automatically reassumes the

state it was in when it was last switched off.

AUTOMATIC CONTROL (rEG) – Automatic control is the normal

functioning state of the controller.

During automatic control it is possible to visualize the control power

on the display by pushing key “UP”.

The range of the power values goes from H100 (100% of the output

power with reverse action) to C100 (100% of the output power with

direct action).

CONTROL OFF (OFF) – The instrument can be swapped into the

“OFF” state, i.e. the control and the relative outputs are deactivated.

The alarm outputs are instead working normally.

BUMPLESS MANUAL CONTROL (OPLO) – By means of this

option it is possible to manually program the power percentage

given as output by the controller by deactivating automatic control.

When the instrument is swapped to manual control, the power

percentage is the same as the last one supplied and can be

modified using the “UP” and “DOWN” keys.

As in the case of automatic control, the programmable values range

from H100 (+100%) to C100 (-100%).

To return to automatic control, select "rEG" in the selection menu.

2.5 - ACTIVE SET POINT SELECTION

This instrument permits pre-programming of up to 4 different Set

points (“SP1”, “SP2”, “SP3”, “SP4”) and then selection of which

one must be active. The maximum number of Set points is

determined by the par. "nSP" located in the group of parameters “

]

SP “.

The active Set point can be selected :

- by parameter "SPAt" in the group of parameters “

]

SP “.

- by key “U” if par. "USrb" = CHSP

- Automatically between SP1 and SP2 if a time “dur.t” (see par. 4.8)

has been programmed.

Set Points “SP1”, “SP2”, “SP3”, “SP4” will be visible depending on

the maximum number of Set Points selected on par. “nSP” and they

can be programmed with a value that is between the value

programmed on par. “SPLL” and the one programmed on par.

“SPHL”.

Note : in all the following examples the Set point is indicated as

"SP", however the instrument will act according to the Set point

selected as active.

3 - INFORMATION ON INSTALLATION AND USE

3.1 - PERMITTED USE

The

instrument

has

been

projected

and

manufactured as a measuring and control device to

be used according to EN61010-1 for the altitudes

operation until 2000 ms.

The use of the instrument for applications not

expressly permitted by the above mentioned rule must adopt all the

necessary protective measures.

The instrument CANNOT be used in dangerous environments

(flammable or explosive) without adequate protection.

The installer must ensure that EMC rules are respected, also after

the instrument installation, if necessary using proper filters.

Whenever a failure or a malfunction of the device may cause

dangerous situations for persons, thing or animals, please

remember that the plant has to be equipped with additional devices

which will guarantee safety.

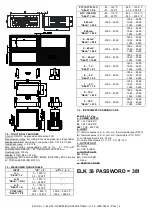

3.2 – MECHANICAL MOUNTING

The instrument, in case 33 x 75 mm, is designed for flush-in panel

mounting.

Make a hole 29 x 71 mm and insert the instrument, fixing it with the

provided special bracket.

We recommend that the gasket is mounted in order to obtain the

front protection degree as declared. Avoid placing the instrument in

environments with very high humidity levels or dirt that may create

condensation or introduction of conductive substances into the

instrument.

Ensure adequate ventilation to the instrument and avoid installation

in containers that house devices which may overheat or which may

cause the instrument to function at a higher temperature than the

one permitted and declared.