15

Installation

Gas train description

The burner's scope of delivery may

include a gas train. In this case, the bur-

ner and the gas train are issued with a

CE Declaration of Conformity. If the gas

train is not delivered with the burner, the

conformity of the burner is valid only if

the gas fittings and instruments and the

design of the gas train satisfy the bur-

ner test specified by EN 676 and meet

the Pressure Equipment Directive. Indi-

vidual testing will be necessary where

this is not the case.

The gas train delivered has its own

documentation including operating

instructions and a spare parts list.

There follows a general description of

the gas train.

Gas trains with a double valve are

intended for the supply, main shut-off,

gas filtration, gas pressure regulation

and monitoring of the gas supply. They

are compatible for use with gases con-

forming to the specifications of the gas

fittings and instruments. They are built

in accordance with EN 676. All function

parts have been individually tested and

awarded the CE marking and number

of the Notified Body. The preassembled

gas train is checked for leaks in the fac-

tory.

Low- and high-pressure gas

trains

If the outlet side of the regulator, i.e.

individual fittings and instruments

downstream of the gas pressure regula-

tor, has not been designed to be com-

patible with the maximum supply

pressure that occurs in the event of a

fault, the gas train must be equipped

with a safety shut-off valve (SSV) and a

safety relief valve (SRV) in accordance

with EN 676. This equipment is gene-

rally required for maximum supply pres-

sures of >360 mbar and > 500 mbar

respectively. These are known as high-

pressure gas trains.

If all fittings and instruments of the gas

train have been designed/approved for

the maximum supply pressure that

occurs in the event of a fault, the gas

train is known as a low-pressure gas

train. This is the case, depending on

component selection, for maximum

supply pressures of 360 and 500 mbar.

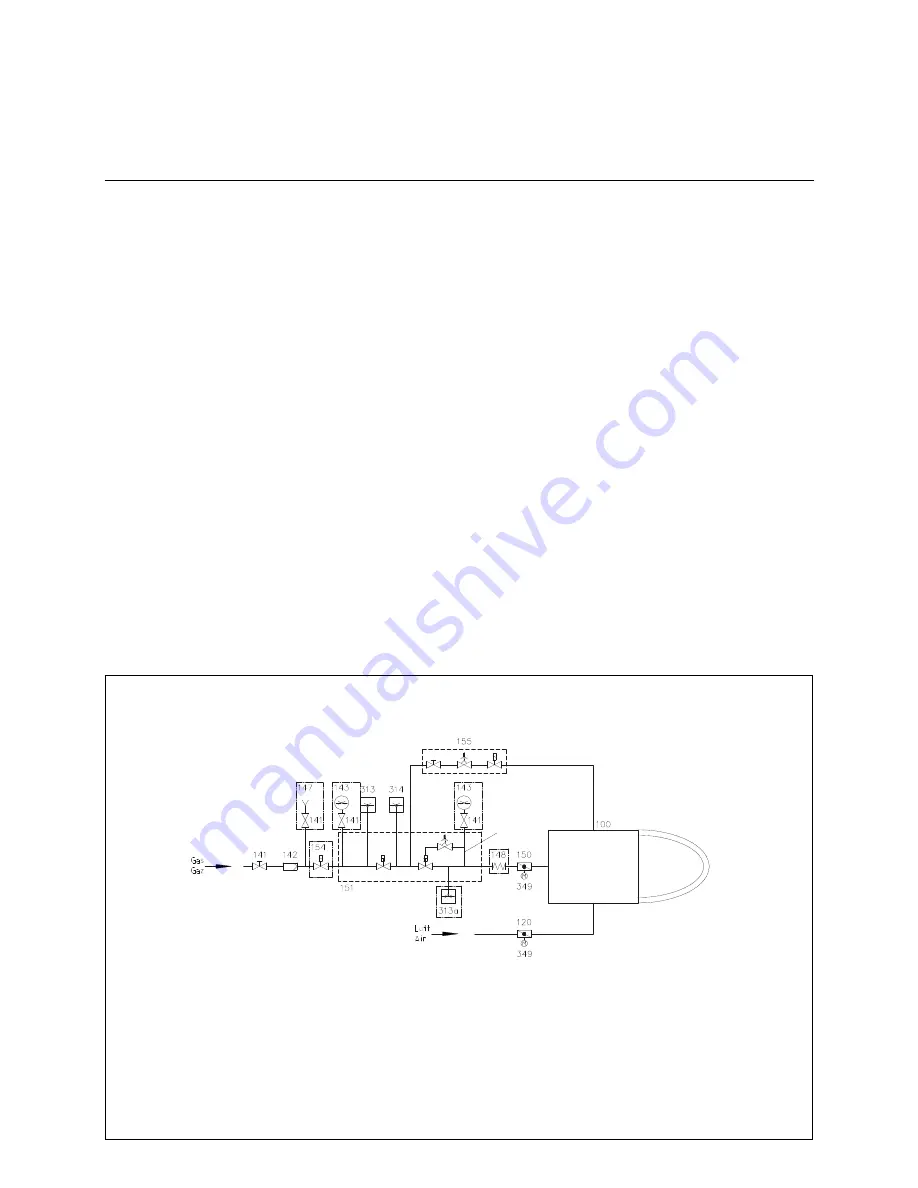

101

100

Burner

101

Impulse pipe gas pressure

120

Air flap

141

Ball valve

142

Gas filter

150

Gas control butterfly

151

Gas double valve (Siemens system illustrated)

155

Ignition unit

313

Min. gas pressure switch

314

Gas pressure switch for valve leak check or valve leak

checker

349

Actuator

Options in accordance with country-specific requirements:

143

Pressure gauge with pushbutton valve

147

Test burner with pushbutton valve

148

Compensator

154

Gas safety valve (additional)

313a Max. gas pressure switch

Gas train to EN 676, low pressure

12/2011 14 072 205

Summary of Contents for Low-NOx N10.12000.30 G-EU2

Page 33: ...34 Manufacturer s declaration...