16

Installation

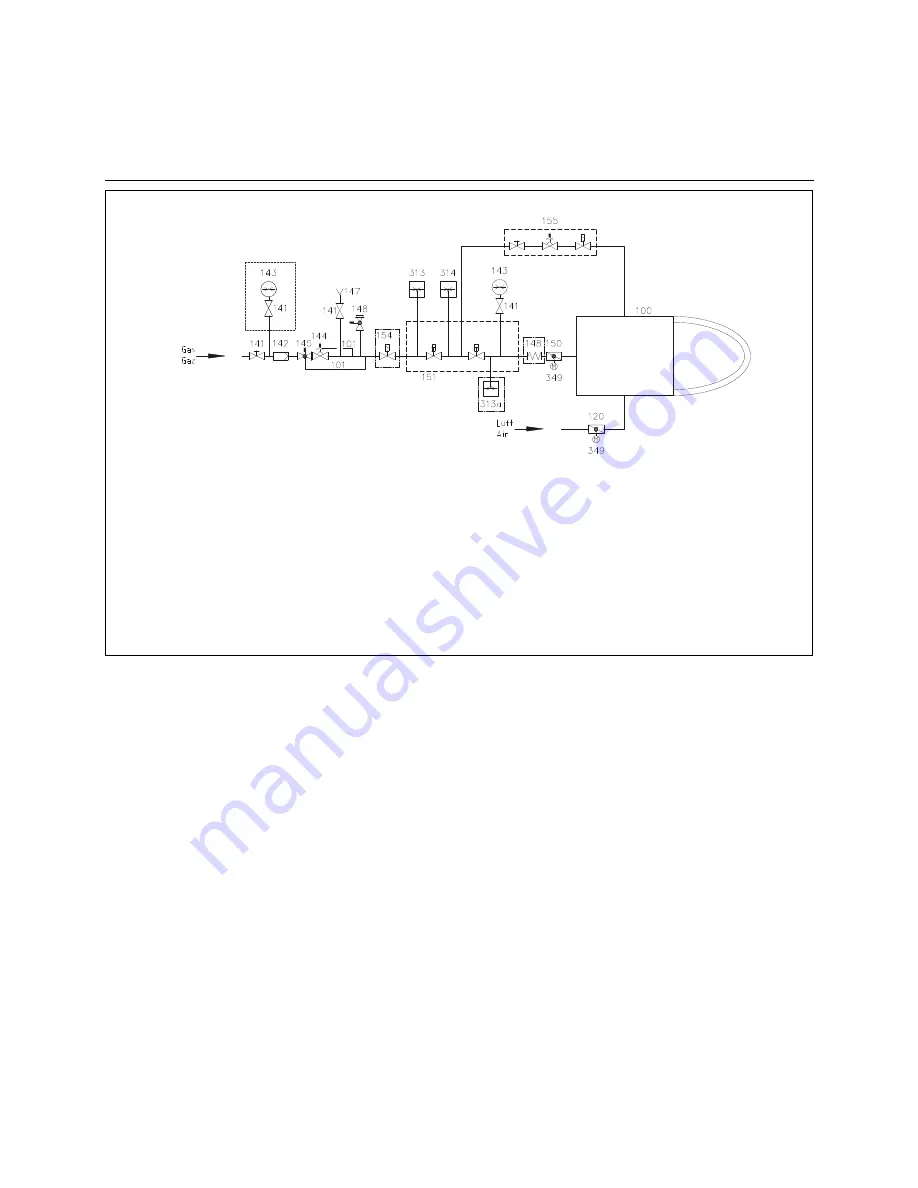

Gas train description

Gas valves and instruments

group

The gas trains must be dimensioned to

suit the throughput required and the

available gas pressure. The gas valves

and instruments group is defined on a

system-specific basis.

The following must be taken into consi-

deration:

• Burner output,

• Combustion chamber counterpres

sure,

• Gas pressure loss in the burner head,

• Gas pressure losses in the gas fit

tings and instruments.

The total drop in gas pressure must

always be lower than the available gas

flow pressure.

100

Burner

101

Impulse pipe gas pressure

120

Air flap

141

Ball valve

142

Gas filter

144

Gas pressure regulator

145

Safety shut-off valve (SSV)

148

Safety relief valve (SRV)

150

Gas control butterfly

151

Gas double valve with integrated gas pressure

regulator (Siemens system illustrated)

155

Ignition unit

313

Min. gas pressure switch

314

Gas pressure switch for valve leak check or valve

leak checker

349

Actuator

Options in accordance with country-specific requirements:

143

Pressure gauge with pushbutton valve

147

Test burner with pushbutton valve

148

Compensator

154

Gas safety valve (additional)

313a Max. gas pressure switch

Gas train to EN 676, high pressure

12/2011 14 072 205

Summary of Contents for Low-NOx N10.12000.30 G-EU2

Page 33: ...34 Manufacturer s declaration...