Trispace AR Floor Standing Shell and TubeBoiler

14 L360

©

MHS Boilers 06/09/2013

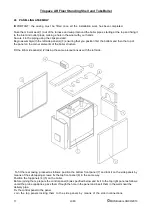

- Ensure that the hydraulic pipes are not used as earth connections for the electrical or telephone system.

They are not suitable for this use and can rapidly deteriorate leading to serious damage.

- Before connecting up the boiler, flush, cleanse and dose all the system pipes to remove any debris that

could affect correct operation.

- If the water available for filling the system is hard (> 15 French degrees) or corrosive (pH < 7.2), a treatment

plant should be provided otherwise permanent damage can occur.

- If the mains water supply contains impurities, a suitable filter must be fitted.

- Avoid any accidental contact between the heating system water and the portable water as the former is not

drinkable.

After connection to the hydraulic system, ensure that the latter is completely de-aerated.

You are advised to insulate the heating system pipes to avoid heat dispersion resulting in increased fuel

consumption and environmental pollution.

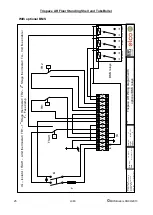

20 ELECTRICAL SYSTEM

The electrical system must comply with the current regulations and be installed by professionally

qualified personnel.

Electrical safety of the equipment is ensured only when it is correctly connected to an efficient earth

system in compliance with the current safety regulations. The manufacturer will not be liable for any

damage caused by failure to earth the system.

Call professionally qualified personnel to check that the electrical system is suitable for the maximum power

absorbed by the equipment, ensuring in particular that the system cable sections are suitable for the

power absorbed by the equipment.

Adapters, multiple sockets and extension leads must not be used for general power supply of the

equipment from the mains.

For connection to the mains, a twin-pole switch must be provided in compliance with the current

regulations.

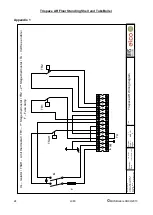

21 THE PROBLEM OF CONDENSATE

The water vapour contained in the products of combustion discharged from the boiler condenses when

the temperature of the water returning to the boiler is below 50°C. Condensation occurs in particular

when the boiler comes on in the morning after being switched off during the night.

The condensation is acid and corrosive and will gradually attack the boiler sheet metal panels.

To limit the formation of condensate as far as possible an anti-condensate pump must be fitted following the

diagram illustrated.

When the burner starts, a thermostat positioned on the water return to the boiler and set to 55°C with

exchange contact will start up the anti-condensate pump which will continue to operate until the set

temperature is reached; the thermostat will then simultaneously switch off the anti-condensate pump and

switch on the system pumps.