Trispace AR Floor Standing Shell and TubeBoiler

19 L360

©

MHS Boilers 06/09/2013

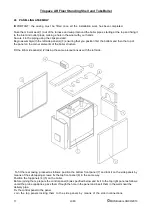

27 FIRST START UP

After performing the preliminary checks, perform the following operations to start the boiler:

- set the boiler thermostat(s) on the control panel between 60 and 90°C according to the

type of installation;

- set the controls to an on position;

-

set the master switch to “on”;

- press the main control panel switch (the button light will come on).

The boiler will perform an ignition phase and, once started, will remain on until the set temperatures have

been reached.

Operation will be automatic from now on.

28 CHECKS DURING AND AFTER INITIAL START-UP

Once the boiler has been started, check that it stops and then starts again by:

- altering the boiler thermostat setting;

- turning the control panel main switch off;

- altering the setting of the control thermostat.

Check the seal on all the gaskets on the water and combustion side; they must be further tightened while hot

in order to guarantee a perfect seal.

This operation is of fundamental importance for the gaskets of the door, of the burner plate and of the smoke

box to prevent leakage of toxic and therefore hazardous combustion fumes into the boiler room.

The weight of the overhanging burner tends to loosen the gasket of the burner plate and the door at the top

It is also very important to check the boiler/flue coupling seal for the above reasons.

Check correct rotation of the pumps.

Check total stoppage by means of the master switch.

Once all the conditions are satisfied, the burner must be correctly set to the maximum power

permitted by the boiler, analysing the combustion products to obtain correct combustion and lowest

possible emission of contaminants.

Ideal flue gas temperature during normal operation is approximately 90 to110°C.

Given that the pressure of the water contained in the system increases during operation, ensure that

its maximum value does not exceed the boiler boiling pressure.